+86 19720579616

+86 19720579616

Zalo

Zalo

In the realm of industrial applications, the choice of valves plays a crucial role in ensuring operational efficiency and safety. Among the myriad of options available, DIN Bellows Sealed Gate Valves stand out due to their unique design and functional advantages. These valves utilize a bellows sealing mechanism that effectively isolates the valve body from the media flowing through, minimizing the risk of leakage and enhancing the overall reliability of the system. As industries increasingly prioritize sustainable practices and stringent environmental regulations, the need for robust and leak-proof solutions becomes paramount.

The implementation of DIN Bellows Sealed Gate Valves in various sectors, such as oil and gas, chemical processing, and water management, offers numerous benefits that significantly contribute to improved performance and safety standards. From their ability to handle high-pressure conditions to their long service life, these valves are engineered to meet the demanding requirements of modern industrial environments. By understanding the top ten advantages of using DIN Bellows Sealed Gate Valves, professionals in the field can make informed decisions that align with both operational goals and regulatory compliance. The following sections will delve into the comprehensive benefits these valves bring to industrial applications, underscoring their importance in today's competitive landscape.

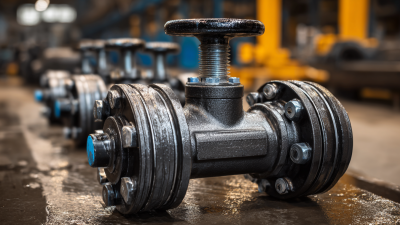

DIN bellows sealed gate valves are widely recognized for their efficiency and reliability in various industrial applications. One of the key features of these valves is their ability to provide a robust sealing mechanism. The bellows design offers enhanced protection against leakage by eliminating the need for traditional packing materials that can degrade over time. This results in a longer service life and minimizes maintenance requirements, making them highly desirable in sectors where containment is critical, such as chemical processing and pharmaceuticals.

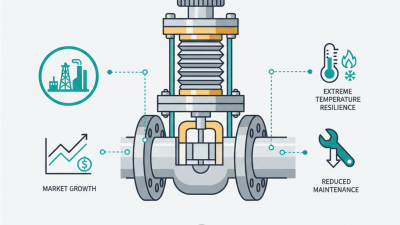

Another significant characteristic of DIN bellows sealed gate valves is their excellent resistance to corrosion and adverse environmental conditions. Constructed from high-quality materials, these valves can withstand challenging operating conditions, including high temperatures and pressures. This durability ensures that they perform reliably, even in demanding applications. Additionally, their compact design facilitates easy installation and integration into existing systems, further enhancing their utility in industrial settings where space can be a constraint. Overall, the combination of effective sealing, durability, and ease of integration makes DIN bellows sealed gate valves an essential component in modern industrial processes.

DIN bellows sealed gate valves are gaining popularity in industrial applications, particularly due to their outstanding ability to prevent leakage and contamination. The design features a flexible bellows that isolates the valve stem from the fluid flow, ensuring that any potential leaks are contained within the bellows structure. This leads to increased operational safety and minimizes the risk of hazardous materials escaping into the environment. Additionally, the elimination of packing glands reduces wear over time, resulting in a longer lifespan for the valve and improved reliability.

When selecting DIN bellows sealed gate valves, consider the following tips:

The advantages of DIN bellows in preventing contamination extend beyond mere leakage prevention. By ensuring that no fluid can escape, these valves significantly reduce the risk of environmental pollution. Moreover, they safeguard the integrity of the system itself, as external contaminants are kept at bay. Industries such as pharmaceuticals, food and beverage, and chemical processing especially benefit from these features, as they uphold stringent safety and quality standards.

DIN bellows sealed gate valves are increasingly utilized across various industrial applications due to their inherent advantages related to sealing and reliability. Industries such="color: #007BFF; font-weight: bold;" processed, water treatment, and power generation benefit significantly from these valves. According to a recent report from the Industrial Valve Market Analysis, the demand for valves tailored for high-pressure and high-temperature environments is projected to rise by 6% annually through 2025. This growth is driven partly by the need for enhanced safety and efficiency in fluid control, where DIN bellows sealed gate valves are particularly effective.

These valves feature a unique design that incorporates a metal bellows, which provides a robust seal against leaks. This characteristic is crucial in sectors where maintaining the integrity of hazardous or sensitive fluids is paramount. A study published in the Journal of Fluid Control highlighted that facilities employing bellows sealed valves reported a 30% reduction in maintenance costs due to lower leak rates and fewer service interruptions. Furthermore, their ability to withstand fluctuating pressures and temperatures makes them an ideal choice for applications in steam lines and aggressive chemical environments, ensuring operational longevity and reliability.

The versatility of DIN bellows sealed gate valves extends to their application in pharmaceutical and food processing industries, where cleanliness and prevention of contamination are critical. Their design not only facilitates effective sealing but also minimizes the risk of product contamination, adhering to strict industry regulations. Reports indicate that using such valves can lead to compliance rates exceeding 95% in hygiene-sensitive applications, underscoring their importance in maintaining production quality and safety standards.

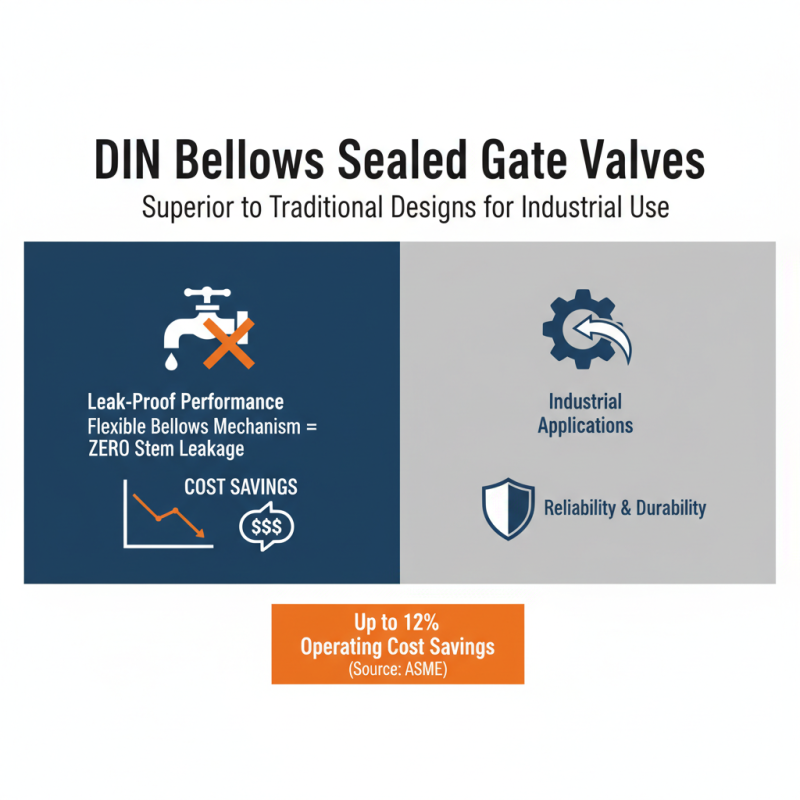

When it comes to meeting the stringent demands of industrial applications, DIN bellows sealed gate valves offer significant advantages over traditional valve designs. One of the primary benefits of bellows sealed valves is their superior leak-proof performance. According to a report by the American Society of Mechanical Engineers (ASME), leakage rates in valves can lead to losses exceeding 12% of operating costs annually in fluid systems. In contrast, DIN bellows sealed gate valves utilize a flexible bellows mechanism that isolates the stem from the flow media, effectively preventing leaks that occur due to stem wear or packing failure. This design enhancement can result in substantial cost savings over time.

Moreover, the durability and reliability of bellows sealed gate valves make them preferable for critical applications. A study published in the Journal of Loss Prevention in the Process Industries highlights that traditional gate valves often require frequent maintenance due to corrosion and erosion issues, leading to extended downtimes. In contrast, the DIN design mitigates these risks by offering enhanced resistance to corrosive environments and minimizing wear factors. The lifespan of DIN bellows sealed gate valves is reported to be at least 30% greater than that of standard valves, giving them a superior total cost of ownership in demanding industrial settings. This durability, combined with reduced maintenance needs, provides a compelling argument for their adoption in industrial processes.

When it comes to the longevity and efficiency of DIN bellows sealed gate valves, careful maintenance is crucial. These valves are particularly popular in industries where leakage prevention is paramount, such as oil and gas, chemicals, and water treatment. A report by the International Society of Automation indicates that proper maintenance can extend the life of these valves by up to 30%, ensuring they function optimally for years. Regular inspections should focus on the integrity of the bellows and the condition of the sealing surfaces, as wear in these areas can lead to potential failures and costly downtime.

In addition to regular inspections, it's important to keep detailed maintenance records. Studies have shown that organizations with comprehensive maintenance logs experience 25% fewer valve-related incidents. This proactive approach allows for better planning in terms of replacement or repair, reducing unplanned outages that can disrupt operations. Moreover, implementing a predictive maintenance strategy, which utilizes condition monitoring technologies, can help identify potential issues before they escalate, optimizing valve performance and contributing to overall operational efficiency.

| Benefit | Description | Maintenance Consideration |

|---|---|---|

| Leak Prevention | Bellows seal design minimizes leakage, enhancing safety in sensitive applications. | Regular inspection of seals to ensure integrity. |

| Durability | Designed to withstand harsh conditions, reducing the need for frequent replacements. | Monitor environmental conditions that could affect valve lifespan. |

| Reduced Maintenance Costs | Lower frequency of repairs results in cost savings over time. | Keep a maintenance log to track service intervals and costs. |

| Versatility | Applicable in various industries including oil, gas, and chemical processing. | Adapt maintenance procedures based on the specific application environment. |

| Ease of Operation | Designed for smooth operation, reducing wear and tear on components. | Lubrication checks to ensure smooth operation are essential. |

| Temperature Resistance | Able to function effectively in extreme temperatures. | Barriers should be in place to prevent thermal shocks. |

| Pressure Management | Can handle high-pressure applications without failure. | Regularly test pressure levels to prevent overloading. |

| Corrosion Resistance | Materials used are often resistant to corrosion, extending valve life. | Inspect for signs of wear and corrosion regularly. |

| Safety Features | Designed with safety mechanisms to prevent accidental discharges. | Train personnel on safety operations during maintenance. |

| Environmental Friendliness | Fewer leaks contribute to a reduced environmental impact. | Ensure compliance with environmental regulations during checks. |