+86 19720579616

+86 19720579616

Zalo

Zalo

In the realm of industrial applications, the efficiency and reliability of valve systems play a pivotal role in maintaining operational standards and ensuring safety. Among the various types of valves available, Din Bellows Sealed Gate Valves stand out due to their unique design and functionality. These valves are engineered to provide superior sealing performance, effectively preventing leakage and contamination in critical processes.

The adoption of Din Bellows Sealed Gate Valves offers numerous advantages, making them an ideal choice for industries where precision and safety are paramount. Their innovative bellows design not only enhances the lifespan of the valve but also minimizes maintenance requirements, allowing for seamless operation over extended periods. Furthermore, these valves are capable of withstanding high pressures and temperatures, making them versatile for various applications, including those in the oil and gas, chemical processing, and water treatment sectors.

In conclusion, the benefits of using Din Bellows Sealed Gate Valves are significant, leading to improved operational efficiency and safety. By understanding their key advantages, industries can make informed decisions that bolster their infrastructure and enhance performance outcomes.

Din bellows sealed gate valves are increasingly recognized for their reliability and efficiency within various industrial applications. One of their key features is the bellows design, which provides a robust barrier against leakage, enhancing the valve's sealing capabilities. According to a recent report from the Valve Manufacturers Association, nearly 30% of industries report significant loss due to leakage in traditional valves, highlighting the importance of a solution like din bellows sealed gate valves. The integrity of the bellows construction not only minimizes the risk of environmental contamination but also ensures optimal performance in high-pressure and high-temperature environments.

Another notable feature of these valves is their ability to operate with minimal maintenance requirements. The bellows mechanism eliminates the need for packing, which traditionally requires regular adjustment and replacement. Data from the International Journal of Industrial Valves indicates that maintenance costs can account for up to 25% of total operational expenses in some sectors; however, by reducing these costs through the use of bellows sealed designs, companies can enhance their long-term profitability. Furthermore, their adaptability in corrosive and difficult operating conditions makes them a preferred choice in industries such as chemical processing, oil and gas, and wastewater management, where durability and reliability are paramount.

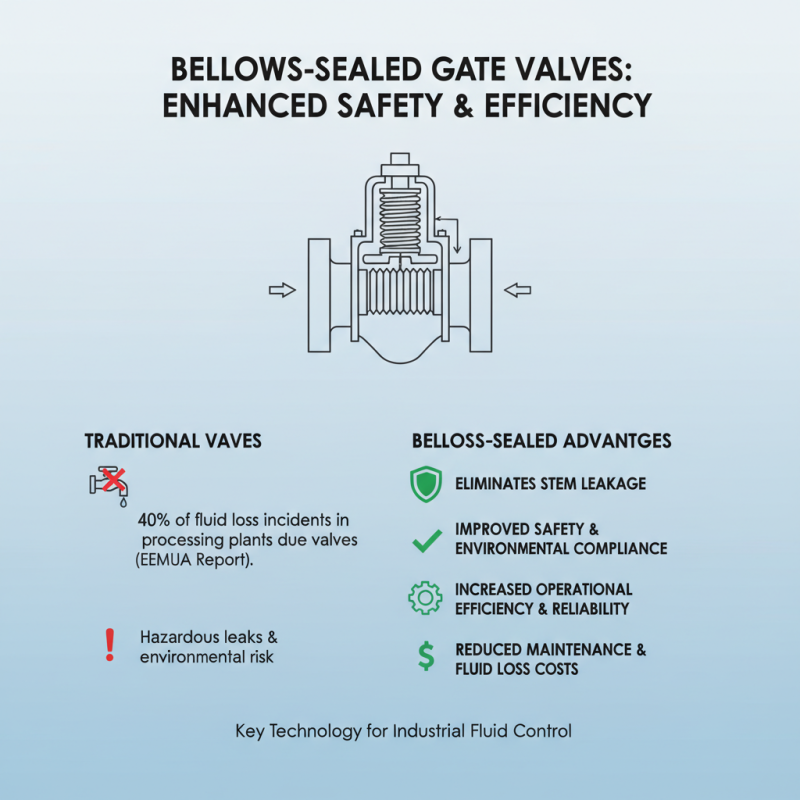

Bellows sealed technology in gate valves has become increasingly popular in industrial applications due to its numerous advantages in enhancing operational efficiency and safety. This technology utilizes elastic bellows to create a tight seal, which prevents leakage of hazardous fluids and gases. According to a report from the Engineering Equipment and Materials Users Association (EEMUA), industrial valves account for approximately 40% of fluid loss incidents in processing plants. By implementing bellows sealed valves, facilities can reduce such incidents significantly, thus improving overall environmental compliance and safety standards.

Another significant benefit of bellows sealed technology is its ability to withstand high pressure and extreme temperatures, making it suitable for a variety of demanding applications. Data from the International Society of Automation (ISA) indicates that bellows sealed valves have a failure rate that is 30% lower than traditional designs under similar conditions. This resilience not only extends the life of the valve but also minimizes maintenance costs, as less frequent replacements and repairs are required. The resultant reduction in downtime can lead to increased productivity and cost efficiency in operations, highlighting the essential role of bellows sealed gate valves in modern industrial practices.

Din bellows sealed gate valves are increasingly recognized for their versatility in various industrial applications. These valves are particularly beneficial in systems dealing with corrosive or hazardous fluids, as their design prevents leakage, significantly enhancing safety and operational efficiency. The bellows seal mechanism provides a robust barrier that eliminates the risk of fluid escaping, making them ideal for oil and gas, chemical processing, and wastewater management industries. Their ability to maintain a tight seal under high pressure and temperature conditions further increases their reliability in demanding environments.

When considering the implementation of din bellows sealed gate valves, it is crucial to assess the specific requirements of your application. For instance, ensure that the materials used in the bellows construction are compatible with the fluids being handled. Additionally, regular maintenance checks can prolong the life of the valve and ensure optimal performance over time.

Tips for enhancing valve performance include conducting periodic inspections for any signs of wear or corrosion and ensuring that the operating conditions remain within the specified limits. Implementing a preventive maintenance schedule can help identify potential issues before they escalate, ensuring that your industrial processes run smoothly and efficiently.

Din bellows sealed gate valves are increasingly favored in industrial applications due to their advanced design and superior performance compared to traditional gate valves. One of the key advantages lies in their ability to provide a hermetic seal, significantly reducing the risk of leakage, which is critical in environments handling volatile or hazardous substances.

According to a report by the Engineering Equipment and Materials Users Association (EEMUA), improper sealing can lead to operational losses upwards of 2% for industrial facilities, highlighting the importance of effective sealing solutions.

In terms of maintenance, bellows sealed gate valves generally require less frequent servicing than their traditional counterparts. The integrated bellows mechanism not only protects the sealing surface from contact with media but also mitigates wear and tear. A comparative analysis from the American Society of Mechanical Engineers (ASME) indicates that plants using bellows sealed valves reported a 30% reduction in maintenance downtime, contributing to overall operational efficiency.

Tips: When considering valve options for your facility, evaluate the specific application needs. Bellows sealed gate valves are ideal for high-pressure and corrosive environments. Furthermore, ensure that the installation and maintenance procedures are strictly adhered to, as this can impact the performance longevity of the valves. Regular inspections can also preemptively address potential issues, reinforcing the reliability of your system.

Bellows sealed valves are critical in maintaining the integrity of fluid systems in various industrial applications. To ensure optimal performance and longevity, adhering to best practices for maintenance and operation is essential. Regular inspection should be the starting point; operators need to check for any signs of wear or damage to the bellows. This includes monitoring for leaks and ensuring the sealing surfaces are clean and free from contamination. Lubrication points should be checked and maintained according to manufacturer specifications, as proper lubrication minimizes friction and wear during operation.

Furthermore, the operation of bellows sealed valves requires careful attention to avoid unnecessary stress on the components. Operators should adhere to the specified pressure and temperature limits to prevent excess strain on the bellows. During operation, gradual opening and closing of the valves are recommended to avoid shock loads that can compromise their function. Training staff in these best practices not only enhances the efficiency of the valves but also extends their lifecycle, reducing the frequency of replacements and the associated downtime in industrial processes. By implementing these maintenance protocols and operational guidelines, facilities can ensure reliable performance and enhanced safety in their fluid handling systems.

| Benefit | Description | Maintenance Best Practice |

|---|---|---|

| Leak Prevention | Bellows sealed design ensures minimal leakage, critical in high-pressure applications. | Regularly inspect for wear or damage on bellows. |

| Extended Lifespan | Robust construction leads to prolonged operational life. | Implement routine maintenance checks to identify signs of fatigue. |

| Corrosion Resistance | Materials selected for the valve inhibit rust and corrosion. | Use appropriate cleaning methods to avoid damaging protective layers. |

| Temperature Control | Bellows allow for thermal expansion without compromising performance. | Monitor operating temperatures to ensure they remain within recommended limits. |

| Easy Maintenance | Simplified design allows for straightforward inspection and servicing. | Follow manufacturer guidelines for maintenance procedures and intervals. |