+86 19720579616

+86 19720579616

Zalo

Zalo

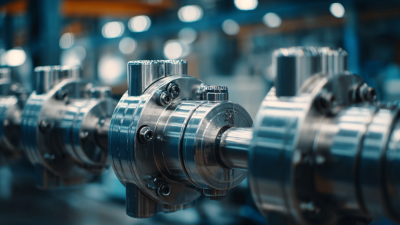

In the realm of modern industrial applications, ensuring the efficient regulation of fluid flow is paramount, and this is where Forged Steel Globe Valves shine. Renowned for their robust construction and reliability, these valves are crucial components in various sectors, including oil and gas, water treatment, and power generation. Understanding the benefits and applications of Forged Steel Globe Valves not only allows industries to optimize their processes but also enhances safety and longevity in operations. With their ability to withstand high pressures and temperatures, these valves offer superior performance, making them a preferred choice for engineers and technicians alike. This article delves into the unique advantages of Forged Steel Globe Valves, providing essential tips for their selection and proper application in contemporary industrial settings.

Forged steel globe valves are pivotal in high-pressure applications across various industries due to their robust construction and reliability. These valves are designed to withstand significant pressure and temperature fluctuations, making them suitable for environments such as oil and gas, power generation, and chemical processing. The forging process imbues the steel with enhanced strength and durability, enabling these valves to handle extreme conditions without compromising their integrity.

Forged steel globe valves are pivotal in high-pressure applications across various industries due to their robust construction and reliability. These valves are designed to withstand significant pressure and temperature fluctuations, making them suitable for environments such as oil and gas, power generation, and chemical processing. The forging process imbues the steel with enhanced strength and durability, enabling these valves to handle extreme conditions without compromising their integrity.

Moreover, the flow control characteristics of forged steel globe valves are highly advantageous in precision applications. Their spherical design allows for smooth regulation of fluid flow, minimizing turbulence and enhancing efficiency. This level of control is essential in high-pressure systems where any leakage or malfunction could lead to catastrophic failures. As a result, engineers often prefer forged steel globe valves to ensure safety and operational efficiency in critical applications. The combination of strength, reliability, and precise flow control underscores the importance of these valves in modern industrial settings.

Forged steel globe valves are increasingly recognized for their versatility and reliability across various industries. Key sectors leveraging these valves include oil and gas, chemical processing, and power generation. In the oil and gas industry, forged steel globe valves are essential for regulating flow and pressure in pipeline systems, ensuring safe and efficient operations under extreme conditions.

According to recent industry statistics, these valves account for over 30% of the total valve market in this sector, highlighting their critical role in maintaining system integrity.

In the chemical processing industry, the demand for forged steel globe valves is driven by their ability to handle corrosive media and high-pressure environments. These valves provide superior sealing capabilities, reducing the risk of leaks and ensuring compliance with safety regulations. Reports indicate that approximately 25% of chemical plants utilize forged steel globe valves in their operations, underscoring their importance in enhancing process reliability and efficiency. Furthermore, power generation facilities benefit from these valves in steam and water control applications, where precise flow regulation is vital for performance and safety. The adoption of forged steel globe valves in these key industries illustrates their indispensable role in modern industrial applications.

Forged steel globe valves are increasingly recognized for their superior performance metrics compared to other valve types, making them a preferred choice in various modern industries. According to a report by Research and Markets, the global valve market is expected to grow significantly, driven by the demand for efficient flow control devices like forged steel globe valves. These valves exhibit exceptional strength and durability, enabling them to withstand high pressures and temperatures, with a performance rating that often exceeds ANSI standard specifications.

In comparison with ball or gate valves, forged steel globe valves are noted for their superior throttling capability and reliable sealing. According to the Valve Manufacturers Association, globe valves can achieve a leakage rate as low as 0.01% at a pressure differential of up to 6,000 psi. This remarkable sealing capability not only enhances operational efficiency but also reduces maintenance costs over time. Additionally, the performance longevity of forged steel globe valves can be attributed to their robust construction, which is less susceptible to wear compared to other valve types, allowing industries such as oil and gas and power generation to achieve optimal flow control and system integrity.

Forged steel globe valves offer significant cost efficiency when evaluated over their entire lifecycle. The initial investment may seem higher compared to other valve types, but their durability and reliability lead to substantial long-term savings. These valves are designed to withstand high pressures and temperatures, which reduces the frequency of replacements and repairs. Consequently, industries can minimize downtime and operational costs. Furthermore, the robust construction of forged steel globe valves ensures they can handle stringent operating conditions, making them a preferred choice in critical applications.

Additionally, the maintenance costs associated with forged steel globe valves are relatively low. Their simple design allows for easy maintenance procedures, which can be performed quickly, thus reducing labor costs. The efficient flow regulation also contributes to energy savings by optimizing resource usage across various industrial processes. Over time, the enhanced efficiency and reduced need for frequent replacements culminate in a significant return on investment, underscoring the long-term financial benefits of adopting forged steel globe valves in modern industrial settings.

Forged steel globe valves are widely recognized for their durability and effectiveness in regulating fluid flow within various industrial applications. To ensure their longevity and optimal performance, regular maintenance is essential. A proactive maintenance approach not only extends the lifespan of these valves but also enhances overall system reliability.

One effective tip for maintaining forged steel globe valves is to conduct routine visual inspections. Look for signs of wear, such as corrosion, leaks, or irregular valve movement. Early detection of issues can prevent minor problems from escalating into major repairs. Additionally, it's crucial to regularly lubricate the valve stems to reduce friction and prevent sticking, especially in high-temperature environments.

Another important practice is to ensure proper cleaning of the valves. Accumulated debris can hinder performance and lead to unexpected failures. Cleaning can be done using appropriate solvents that do not harm the valve’s material. Furthermore, developing a maintenance schedule that includes cylinder pressures and operational checks can significantly contribute to more efficient valve operation and lifespan. In summary, following these maintenance best practices can help keep forged steel globe valves operating smoothly in any modern industrial setting.