+86 19720579616

+86 19720579616

Zalo

Zalo

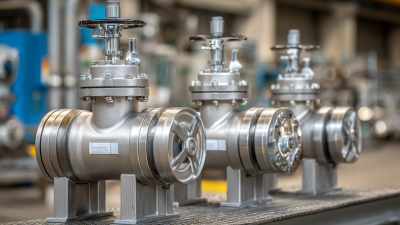

In the realm of modern industrial applications, API Bellows Sealed Globe Valves have emerged as a critical component in enhancing system reliability and safety. According to a report by MarketsandMarkets, the global valve market is projected to reach USD 91.4 billion by 2025, driven by the increasing demand for sophisticated flow control systems across various sectors, including oil and gas, water and wastewater management, and chemical processing. API Bellows Sealed Globe Valves, designed to minimize emissions while providing an efficient flow regulation solution, play a pivotal role in meeting both environmental standards and operational efficiency. These valves are engineered with a unique sealing feature that prevents leakage, adhering to stringent industry regulations and ensuring maximum performance. As industries increasingly pivot towards advanced technology solutions, understanding the significance of these valves becomes essential for optimizing processes and maintaining compliance in a competitive market.

API bellows sealed globe valves are designed to provide a reliable seal that prevents leaks, which is crucial in many industrial applications. Their unique features include a bellows assembly that isolates the valve stem from the process fluid, eliminating potential leak paths. This design not only enhances safety by minimizing the risk of hazardous substances escaping but also reduces the need for frequent maintenance, making them an efficient choice for industries such as oil and gas, chemicals, and power generation.

In addition to their safety features, API bellows sealed globe valves offer excellent thermal stability and can handle varying temperatures and pressures. The materials used in their construction are often resistant to corrosion and wear, ensuring a longer operational life. This durability translates into cost savings for companies, as they face fewer repairs and replacements over time. With growing environmental regulations and the need for sustainable practices, these valves play a pivotal role in modern industry by providing effective control of fluid flow while adhering to safety standards.

API Bellows Sealed Globe Valves are crucial components in various industries, primarily due to their ability to minimize fugitive emissions and enhance operational reliability. These valves are designed with a unique bellows seal that prevents leakage, making them ideal for applications in industries such as oil and gas, chemical processing, and water treatment. As industry standards evolve, there are new opportunities and incentives for companies to adopt cutting-edge valve solutions that address environmental concerns and regulatory compliance.

One significant trend is the focus on enhanced stem sealing methods, including the use of compression packing, which has gained traction thanks to global standards advocacy. This shift underscores the importance of selecting the right valve technology to reduce emissions while maintaining efficiency. For industries reliant on fluid control, implementing API Bellows Sealed Globe Valves can lead to improved operational performance and sustainability.

Tips for selecting the right bellows sealed globe valve include assessing the specific application needs, understanding the fluid properties, and considering the operating conditions. Additionally, regular maintenance and performance testing in line with the latest emissions standards can ensure that these valves continue to operate effectively and safely in demanding environments. Balancing quality with compliance not only enhances operational integrity but also supports a commitment to environmental responsibility.

API bellows sealed globe valves are increasingly recognized for their innovative design, which differentiates them significantly from traditional globe valves. Traditional valves often rely on packing and stem seals that can wear down over time, leading to potential leaks. In contrast, bellows sealed globe valves utilize a flexible metallic bellows to eliminate the need for packing, enhancing their reliability and safety in critical applications. According to a market study published by Research and Markets, the demand for such advanced valves is expected to grow by approximately 12% over the next five years, driven by the need for leak-free operation in industries such as oil and gas, chemical processing, and pharmaceuticals.

When considering the installation of valves, one vital tip is to evaluate the specific requirements of your application. API bellows sealed globe valves are especially suited for high-pressure and high-temperature contexts where leakage could lead to severe environmental or safety issues. Additionally, investing in quality assurance during installation is crucial, as improper fitting can negate the benefits of advanced sealing mechanisms.

Another consideration is maintenance. While bellows sealed valves can reduce maintenance needs by minimizing potential leak points, monitoring them regularly is still essential. Implementing a predictive maintenance strategy will prolong the lifespan of these valves and ensure optimal operational performance, aligning with findings from the American National Standards Institute that emphasize the significance of proactive maintenance in modern industrial processes.

API bellows sealed globe valves are essential components in various industrial applications, particularly in sectors requiring high reliability and minimal leakage. The maintenance of these valves is crucial for ensuring long-term functionality and optimal performance. According to a report by the American Petroleum Institute, improper maintenance can lead to a decrease in performance by up to 30%, significantly impacting operational safety and efficiency. Regular inspections and adherence to manufacturer guidelines are vital in prolonging the lifespan of these valves.

In addition to routine maintenance, the choice of materials for bellows sealed globe valves plays a critical role in their longevity. Research indicates that using high-quality alloys can enhance resistance to corrosive environments, thus reducing the frequency of maintenance interventions. A study published in the Journal of Pressure Vessel Technology highlights that valves constructed with specialized materials can exhibit a 50% increase in service life compared to standard options. This underlines the importance of material selection not just for durability but also for maintaining the integrity of the overall system in demanding industrial environments.

API bellows sealed globe valves have emerged as a significant innovation in modern engineering, primarily due to their ability to enhance reliability and performance in various industrial applications. These valves feature a unique design that incorporates bellows to provide a superior seal, minimizing the risk of leaks in critical systems. With the increasing demand for advanced valve solutions across industries such as oil and gas, the importance of these API-compliant valves has never been more pronounced. Their robust construction and effectiveness make them ideal for environments where reliability is paramount, reflecting the industry's ongoing commitment to safety and efficiency.

In recent years, innovative applications of API bellows sealed globe valves have been observed in several sectors, addressing essential needs while adhering to stringent regulations. For instance, advancements in valve technologies have played a crucial role in overcoming transportation challenges in sectors like rail transport, where maintaining system integrity is essential for operational efficiency. Moreover, the offshore market continues to see the integration of these valves into solutions designed to meet demanding environmental standards, demonstrating a proactive approach to sustainability in engineering practices. As industries evolve and face new challenges, the role of API bellows sealed globe valves will undoubtedly expand, underpinning a future defined by reliability and sustainable engineering solutions.