+86 19720579616

+86 19720579616

Zalo

Zalo

In the ever-evolving landscape of modern industrial applications, the importance of reliable and efficient valve systems cannot be overstated. According to a recent market analysis by Research and Markets, the global industrial valve market is projected to reach USD 130 billion by 2025, with an increasing demand for high-performance components in the oil and gas, chemical, and water treatment sectors. Among these, API Bellows Sealed Gate Valves stand out due to their unique design, which provides a superior sealing capability that prevents leakage, thereby enhancing operational safety and reducing environmental risks.

In the ever-evolving landscape of modern industrial applications, the importance of reliable and efficient valve systems cannot be overstated. According to a recent market analysis by Research and Markets, the global industrial valve market is projected to reach USD 130 billion by 2025, with an increasing demand for high-performance components in the oil and gas, chemical, and water treatment sectors. Among these, API Bellows Sealed Gate Valves stand out due to their unique design, which provides a superior sealing capability that prevents leakage, thereby enhancing operational safety and reducing environmental risks.

With the growing emphasis on sustainability and regulatory compliance, the adoption of API Bellows Sealed Gate Valves is becoming essential for industries looking to optimize their processes while maintaining high standards of safety and efficiency. Their ability to withstand extreme conditions and minimize maintenance requirements further solidifies their role as a critical component in the modern industrial ecosystem.

Bellows sealed gate valves play a crucial role in modern industrial applications, particularly in sectors that demand high standards of safety and reliability. These valves are designed to prevent leakage and minimize maintenance costs, making them indispensable in industries such as petrochemicals, hydrogen production, and semiconductor manufacturing. The innovative bellows design provides an extra layer of protection against environmental contaminants, ensuring that operations remain uninterrupted and efficient.

In today's demanding industrial landscape, the importance of dependable sealing solutions cannot be overstated. As industries evolve, the need for advanced control mechanisms and precise fluid management becomes increasingly critical. The use of bellows sealed gate valves enables companies to enhance process control while meeting rigorous regulatory requirements. By integrating these high-performance valves into their systems, industries can achieve greater operational efficiency, reduce the risk of hazardous leaks, and adapt to the complexities of modern production demands.

| Application Area | Key Benefits | Material Compatibility | Temperature Range (°C) | Pressure Rating (PSI) |

|---|---|---|---|---|

| Oil & Gas | Leak-proof performance, durability | Carbon Steel, Stainless Steel | -29 to 300 | 150-600 |

| Chemical Processing | Corrosion resistance, safety | PTFE, Hastelloy | -50 to 200 | 150-300 |

| Water Treatment | Reliable shut-off, reduced leakage | PVC, Ductile Iron | 0 to 80 | 150-250 |

| Power Generation | High performance, low maintenance | Alloy Steel, Nickel Alloys | -40 to 450 | 300-1500 |

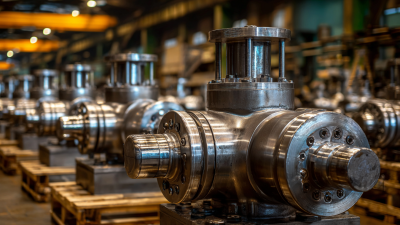

API bellows sealed gate valves are vital components in modern industrial applications, offering unique features that enhance performance and reliability. One of the primary characteristics of these valves is their innovative bellows seal design, which provides a robust barrier against leakage. This design serves not only to contain fluids but also to prevent atmospheric contamination, making them an excellent choice for handling hazardous materials in industries such as oil and gas, chemical processing, and water treatment.

API bellows sealed gate valves are vital components in modern industrial applications, offering unique features that enhance performance and reliability. One of the primary characteristics of these valves is their innovative bellows seal design, which provides a robust barrier against leakage. This design serves not only to contain fluids but also to prevent atmospheric contamination, making them an excellent choice for handling hazardous materials in industries such as oil and gas, chemical processing, and water treatment.

Another significant feature of API bellows sealed gate valves is their ability to withstand extreme pressure and temperature variations. They are constructed from high-quality materials that ensure durability and longevity, which is critical in demanding industrial settings. Furthermore, these valves require minimal maintenance due to their sealing technology, which reduces wear over time. The combination of these attributes ensures that API bellows sealed gate valves can operate efficiently while minimizing the risk of downtime caused by valve failure, thus optimizing overall system performance in various applications.

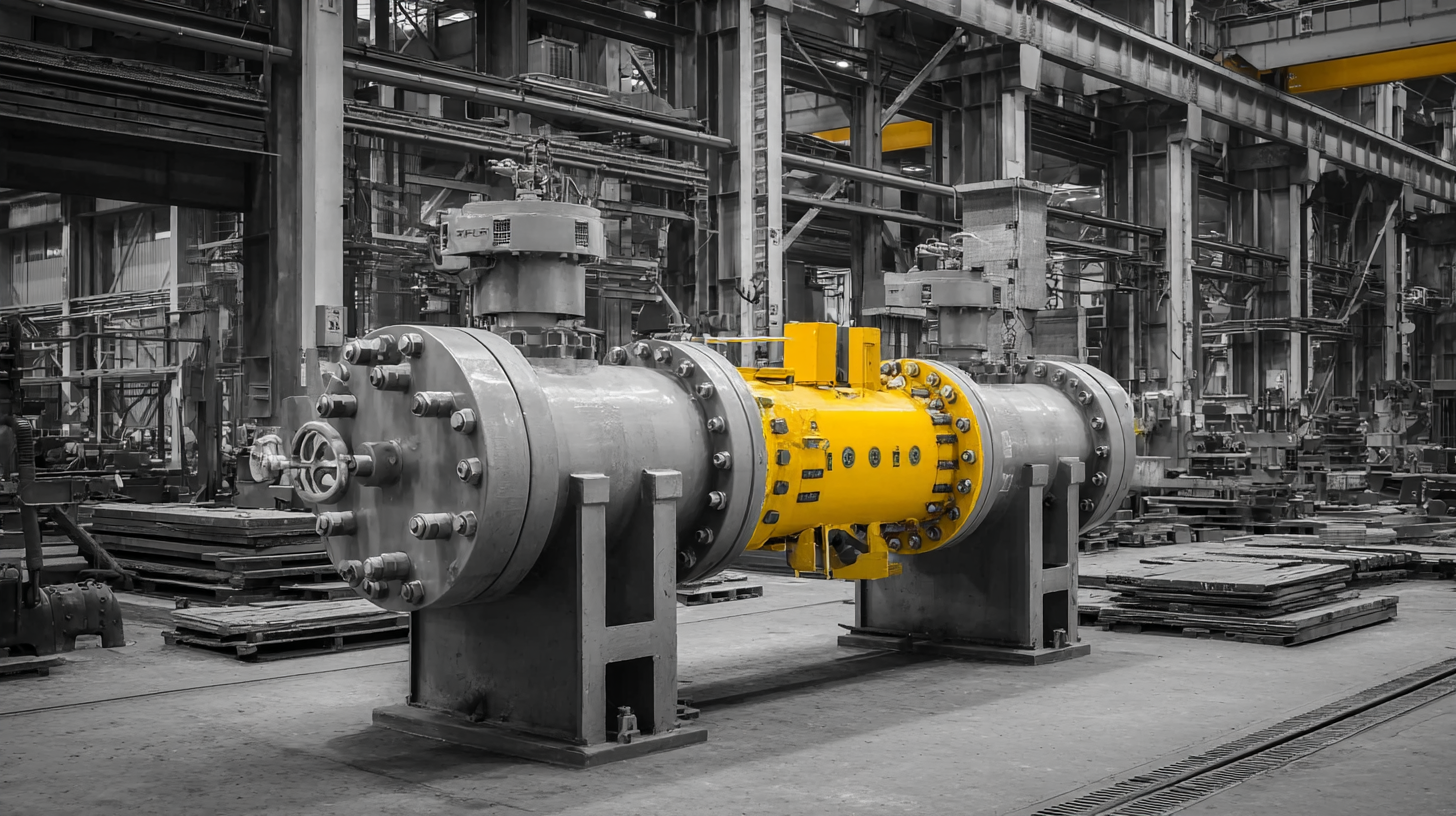

Bellows sealed gate valves have gained significant traction across various industries due to their unique design that prevents leakage and enhances operational safety. In the oil and gas sector, for instance, these valves are critical in managing high-pressure systems where even minute leaks can lead to catastrophic failures. According to a recent report by the International Energy Agency, about 80% of operational incidents in oil and gas pipelines are caused by valve failures. By utilizing bellows sealed gate valves, companies can mitigate these risks, ensuring more reliable and safe operations.

In chemical processing industries, the demand for valves that can handle aggressive media has never been higher. As per a study from Grand View Research, the global valve market is expected to reach $93.9 billion by 2027, with a significant portion driven by the need for durable and leak-proof solutions. Bellows sealed gate valves are particularly advantageous in these environments since they provide a hermetic seal that prevents contamination and maintains the integrity of the chemicals involved.

Tip: Regular maintenance of bellows sealed gate valves is crucial to ensure their longevity and reliability. It is advisable to carry out regular visual inspections and ensure that the bellows are free from any wear or damage. By adopting preventive measures, industries can enhance the performance and lifespan of their valve systems significantly.

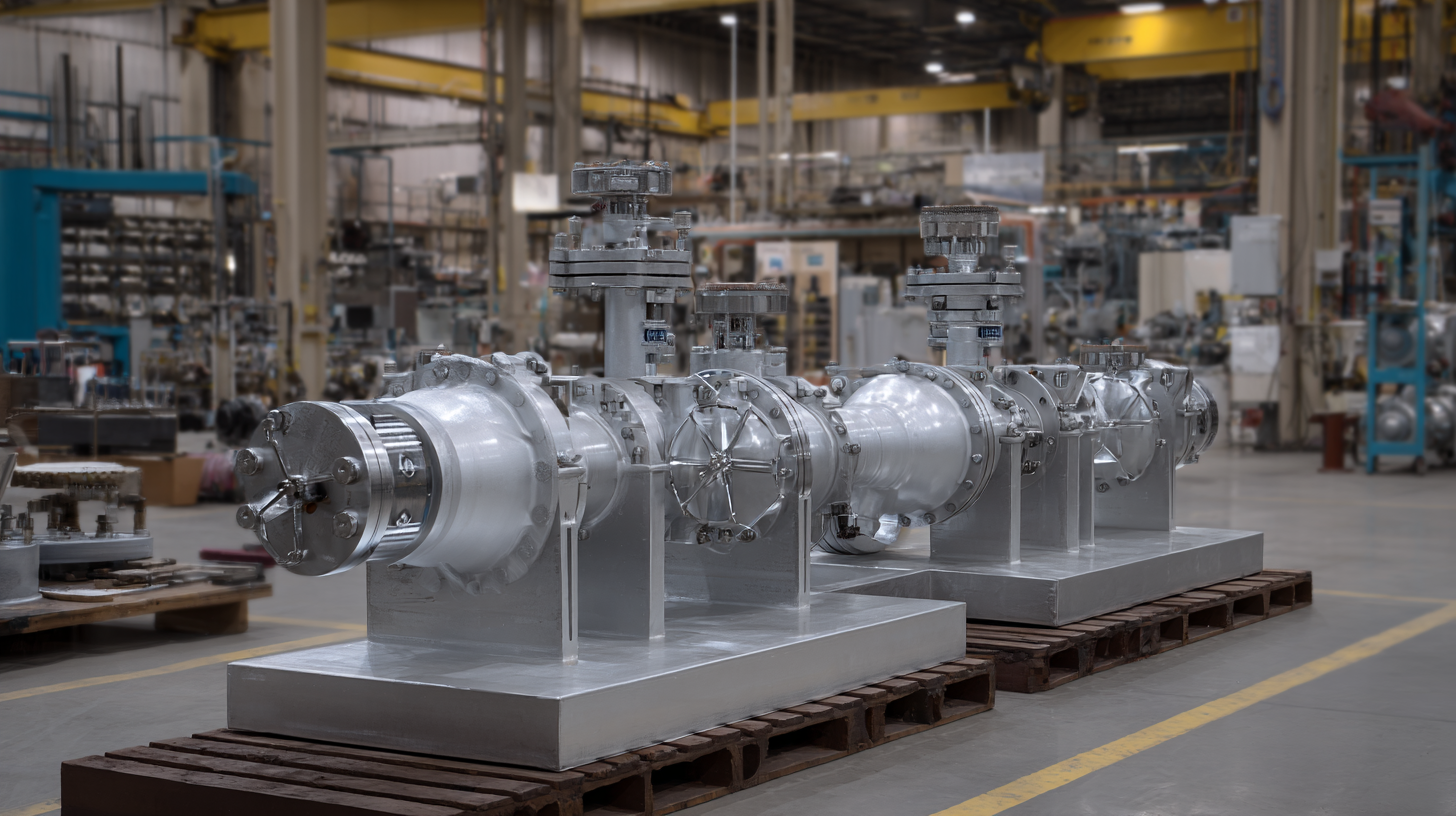

Bellows sealed gate valves offer several advantages over traditional valve models, making them an essential choice for modern industrial applications. One of the key benefits of bellows sealed valves is their ability to prevent leakage. Unlike conventional gate valves that can suffer from packing wear and failure, bellows sealed designs incorporate a flexible metal bellows that effectively isolates the internal fluid from the environment. This containment ensures minimal exposure to hazardous substances, enhancing safety and compliance with environmental regulations.

Moreover, the durability of bellows sealed gate valves is another significant advantage. These valves are engineered to withstand extreme temperatures and pressures, which is crucial in demanding industrial settings. The bellows mechanism can endure thermal cycling without compromising performance, reducing the need for frequent maintenance or replacement. Additionally, the reduced friction in the opening and closing process results in smoother operation and less wear over time, ultimately leading to increased longevity and reliability in system performance.

API bellows sealed gate valves are increasingly recognized for their crucial role in modern industrial applications, particularly due to their maintenance advantages. These valves are designed to prevent leakage of hazardous fluids, making them essential for industries such as oil and gas, chemical manufacturing, and wastewater treatment. According to a recent report by the Global Valves Market, the demand for bellows-sealed valves is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, underlining the importance of reliability and safety in industrial processes.

API bellows sealed gate valves are increasingly recognized for their crucial role in modern industrial applications, particularly due to their maintenance advantages. These valves are designed to prevent leakage of hazardous fluids, making them essential for industries such as oil and gas, chemical manufacturing, and wastewater treatment. According to a recent report by the Global Valves Market, the demand for bellows-sealed valves is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, underlining the importance of reliability and safety in industrial processes.

When it comes to maintenance considerations, regular inspections and preventive maintenance are key to extending the lifespan of API bellows sealed gate valves. Experts recommend implementing a routine maintenance schedule that involves checking for signs of wear and tear, ensuring proper valve alignment, and monitoring the integrity of the bellows. Additionally, training personnel on best practices for operation can significantly reduce the chances of malfunctions, which, according to industry standards, can lead to costly downtime.

Tips: Ensure that the operating environment is as clean and dry as possible to prevent contaminants from affecting valve performance. Additionally, maintaining precise control over operating temperatures can help in prolonging the lifespan of the bellows. Regularly documenting maintenance activities can also facilitate better tracking of valve performance and assist in making informed decisions regarding repairs and replacements.