+86 19720579616

+86 19720579616

Zalo

Zalo

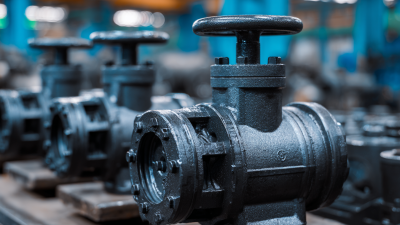

In the realm of industrial applications, the choice of valves plays a crucial role in ensuring efficiency, safety, and longevity of operations. Among the various types of valves available, Din Bellows Sealed Gate Valves stand out for their exceptional design and functionality. These valves are equipped with a specialized bellows seal that provides superior leak resistance, making them ideal for situations where containment is paramount.

The advantages of using Din Bellows Sealed Gate Valves extend beyond just leak prevention; they also include enhanced durability, reduced maintenance costs, and excellent performance in high-pressure environments.

In this blog, we will explore the five best advantages of Din Bellows Sealed Gate Valves, illustrating why they are a preferred choice for industries that demand both reliability and efficiency in their fluid control systems.

Din bellows sealed gate valves are increasingly recognized for their enhanced sealing integrity, making them a favored choice in various industrial applications. The main advantage of these valves lies in their protective bellows that effectively isolate the valve's internal mechanism from external environmental factors. This design not only prevents leakage of fluids but also minimizes the risk of contamination, which is crucial in sensitive applications such as petrochemicals and semiconductor manufacturing.

Moreover, the bellows seal significantly extends the valve's lifespan by reducing wear and tear caused by media corrosion and pressure fluctuations. Industries that require reliable, maintenance-free operation appreciate these features, as they reduce downtime and operational costs. The robustness of bellows sealed gate valves ensures stability under high-pressure conditions, allowing for safe and efficient management of demanding processes. As industrial environments become more rigorous, the integrity and reliability offered by these valves will undoubtedly drive their adoption further.

Din bellows sealed gate valves are increasingly recognized for their superior durability and longevity, making them an ideal choice for various industrial applications. The unique design of these valves, which incorporates a bellows seal, eliminates the risk of fluid leakage that is common in traditional valves. This feature not only enhances safety by reducing the chance of spills in sensitive environments but also minimizes the need for frequent maintenance or replacements, thereby lowering overall operational costs.

Moreover, the longevity of din bellows sealed gate valves translates to fewer interruptions in industrial processes. Their ability to withstand harsh conditions, including extreme temperatures and corrosive substances, ensures reliable performance over extended periods. This resilience not only optimizes productivity but also promotes sustainable practices by reducing waste associated with valve failures. Industries can rely on these valves to maintain smooth operations while contributing to a safer workplace, exemplifying how advanced engineering solutions can effectively meet the demands of modern industrial challenges.

In industrial applications, the reduction of leakage risks has become a paramount concern, especially when it comes to ensuring safety and environmental protection. DIN bellows sealed gate valves are specifically designed to address these issues. Their unique construction, which incorporates a flexible bellows seal, effectively prevents fluid leakage throughout the valve’s operation. This innovative feature not only protects the surrounding environment from potential contamination but also reduces the risk of hazardous materials escaping, ensuring compliance with stringent environmental regulations.

Furthermore, the design of DIN bellows sealed gate valves contributes to longer operational life and maintenance savings. Unlike conventional valves that may rely on packing materials which can wear out and require frequent replacement, the bellows seal maintains its integrity over time. This durability means that industries can significantly lower their maintenance costs and minimize the frequency of valve replacements. The result is not just an economic benefit, but also a substantial reduction in the environmental footprint associated with the disposal of damaged valves and packing materials, making these valves an excellent choice for sustainability-minded operations.

| Advantage | Description | Impact on Industry |

|---|---|---|

| Reduction of Leakage Risks | The bellows design creates a tight seal, minimizing the risk of leakage. | Increases reliability and lowers maintenance costs. |

| Environmental Protection | Reduces the risk of harmful substances escaping into the environment. | Supports compliance with environmental regulations. |

| Durability | Manufactured from robust materials to withstand harsh conditions. | Reduces the frequency of replacements, enhancing operational efficiency. |

| Versatility | Applicable in various industries such as water treatment and petrochemicals. | Increases usability across different applications. |

| Cost-Effectiveness | Long lifespan and reduced maintenance lead to lower overall costs. | Enhances profitability by reducing operational expenditures. |

Din bellows sealed gate valves offer significant benefits, particularly in the realm of streamlined maintenance and cost efficiency. These valves are designed to eliminate the need for frequent replacements and repairs, as their unique construction features a flexible bellows that prevents leakage. This reduces the potential for costly downtimes and extensive maintenance schedules often required by traditional valves, allowing industrial operations to focus resources on productivity instead.

Furthermore, the use of bellows sealed gate valves can lead to long-term savings. Their enhanced durability means less frequent service interruption and a reduction in the overall expense of managing valve systems. Companies can minimize expenses associated with spills and the consequent environmental regulations that arise from them. In this way, investing in high-quality Din bellows sealed gate valves not only ensures the integrity of operations but also provides a more financially prudent choice for industrial applications.

Din bellows sealed gate valves are increasingly recognized for their versatility across a multitude of industrial applications. Their unique design features a flexible bellows that prevents leakage, making them particularly valuable in sectors where fluid control is critical. Industries such as oil and gas, water treatment, and chemical processing benefit significantly from these valves, due to their ability to maintain a tighter seal and withstand high pressures and temperatures. This adaptability allows them to be used in both demanding environments and more standard applications, providing a reliable solution for various fluid media.

One of the notable advantages of din bellows sealed gate valves is their capability to reduce maintenance costs. By eliminating the need for regular packing adjustments, these valves significantly decrease downtime and enhance operational efficiency. Additionally, their design minimizes the risk of contamination, making them ideal for industries like pharmaceuticals and food processing, where purity is essential. Overall, the versatility and reliability of din bellows sealed gate valves make them an excellent choice for enhancing processes across diverse industrial sectors, supporting both operational integrity and safety.