0102030405

Bellows Sealed Valves

Construction of Bellows Sealed Valves

At the heart of a bellows sealed valve is the bellows, a flexible, accordion-like structure typically made from materials such as stainless steel, Inconel, or other corrosion-resistant alloys. This component provides a dynamic seal between the valve stem and the body of the valve, offering multiple advantages over conventional sealing methods like packing.

The construction of a bellows sealed valve involves the following primary components:

Body: The valve body houses the internal components and controls the flow of fluids or gases. It is designed to withstand high pressures and aggressive environments.

Bonnet: The bonnet is the top part of the valve that covers the internal mechanism and holds the bellows in place.

Bellows: This is the key sealing element, typically a thin, corrugated metal that acts as a barrier to prevent leaks. It is designed to expand and contract with the motion of the valve stem.

Valve Stem: The valve stem connects the actuator to the valve mechanism. It moves up and down to control the flow of media.

Actuator: This is the external component that applies force to the valve stem to open or close the valve. It can be manual, pneumatic, or electric.

Main Types of Bellows Sealed Valves

Bellows sealed valves are essential for leak-proof performance in industries handling hazardous or high-purity fluids. The main types include:

Bellows Sealed Globe Valve – Ideal for flow regulation, this valve offers excellent throttling control. The bellows prevent leakage around the stem, making it suitable for high-pressure and high-temperature applications like chemical processing and steam systems.

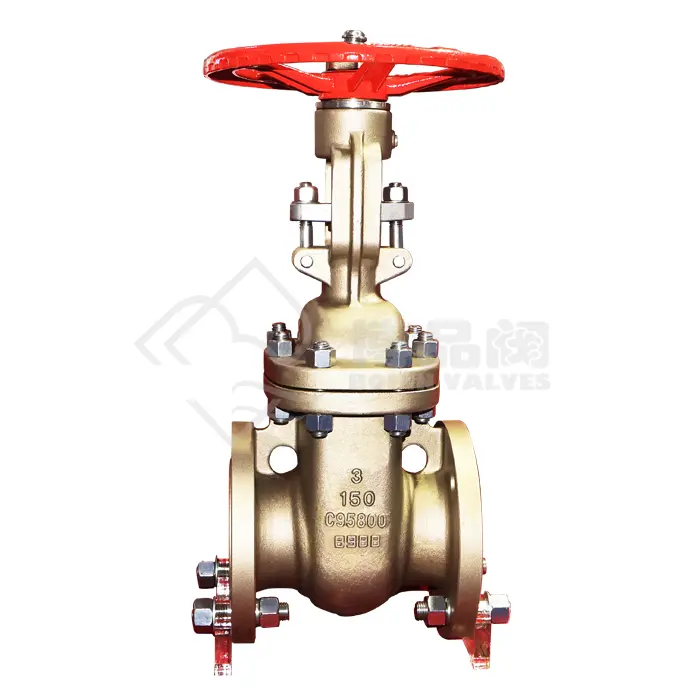

Bellows Sealed Gate Valve – Designed for on/off control, this valve provides a tight shut-off with minimal pressure drop. The bellows ensure zero leakage, making it ideal for oil and gas pipelines and steam distribution.

Bellows Sealed Ball Valve – A quarter-turn valve that allows quick on/off operation. The bellows seal prevents leaks, making it suitable for cryogenic applications and corrosive media handling.

How Bellows Sealed Valves Work

Bellows sealed valves operate on the same basic principles as traditional valves in terms of controlling the flow of liquids or gases, but they utilize the bellows to prevent leakage. The bellows, being a flexible and expandable component, moves with the stem to maintain an airtight seal throughout the valve’s operation.

In a typical bellows sealed valve, when the actuator applies force, the valve stem moves up or down. As the stem moves, the bellows flexes in response, ensuring that no fluid or gas escapes around the stem. This continuous seal is maintained even if the valve stem is actuated multiple times, eliminating the need for packing, which can wear out over time or cause leakage due to improper maintenance.

The valve’s sealing effectiveness is influenced by the material of the bellows, the design of the stem, and the pressure and temperature conditions within the system.

Advantages of Bellows Sealed Valves

There are several benefits to using bellows sealed valves in critical applications:

Leak Prevention: The most significant advantage of bellows sealed valves is their ability to prevent leakage. Traditional valves rely on stem seals, which can degrade or fail over time, allowing harmful or dangerous substances to leak. Bellows seals, however, are more durable and maintain an effective seal throughout the valve’s lifecycle.

Reduced Maintenance: With the bellows acting as a long-lasting seal, the need for frequent maintenance and replacement of packing material is minimized. This reduces downtime and increases the overall efficiency of the system.

Enhanced Safety: Bellows sealed valves are particularly advantageous in industries where leakage could result in safety hazards, such as in nuclear power plants or chemical plants. The ability to maintain a leak-tight seal even under extreme conditions helps prevent accidents and hazardous exposure.

Corrosion Resistance: Since bellows are often made from highly corrosion-resistant materials such as stainless steel or alloys like Inconel, they are ideal for handling aggressive chemicals or extreme environmental conditions.

Temperature and Pressure Tolerance: Bellows sealed valves can handle a wide range of temperatures and pressures, making them suitable for both high-temperature steam systems and cryogenic applications.

Applications of Bellows Sealed Valves

Bellows sealed valves are commonly used in industries where leakage can pose significant risks. Some of the key applications include:

Chemical and Petrochemical Industry: In these industries, valves are required to control the flow of hazardous chemicals, gases, and liquids. Bellows sealed valves ensure that harmful substances do not leak into the environment, reducing the risk of contamination or explosions.

Pharmaceutical and Food Processing: In these sectors, hygiene and safety are of paramount importance. Bellows sealed valves prevent contamination of the product by maintaining a tight seal and avoiding external leaks, which is critical for ensuring the purity of pharmaceuticals and food products.

Oil and Gas Industry: Whether it’s offshore drilling or refining, the oil and gas industry demands valves that can withstand high pressures and temperatures. Bellows sealed valves meet these requirements while preventing the leakage of crude oil, gas, or refined products.

Nuclear Power Plants: In nuclear power plants, valve reliability is essential to the safety and efficiency of the facility. Bellows sealed valves are used to control the flow of fluids in critical systems while ensuring no radioactive materials leak into the environment.

Cryogenic Systems: In applications dealing with cryogenic temperatures, such as liquid oxygen or nitrogen storage, bellows sealed valves provide an effective solution by preventing leaks in sub-zero conditions.

Maintenance and Inspection

Despite their durability and long lifespan, bellows sealed valves do require regular inspection and maintenance to ensure optimal performance:

Visual Inspection: Regular checks should be conducted to ensure the bellows are not damaged or deformed. Signs of wear or cracks could indicate the need for replacement.

Leak Testing: Pressure testing or using leak detection methods (such as helium leak testing) can help identify potential leaks in the valve system. This is particularly important in high-risk industries like pharmaceuticals or nuclear energy.

Lubrication: While bellows seals don’t require traditional packing maintenance, the valve stem and actuator mechanism might need periodic lubrication to ensure smooth operation.

Stem Seal Check: Although the bellows provide a primary seal, it’s also important to inspect the stem seal and ensure it’s functioning correctly to avoid external leakage.

Replacement of Bellows: Over time, due to mechanical wear or extreme environmental conditions, the bellows might need to be replaced. This is typically done when the bellows show signs of fatigue or after a certain number of cycles.

Challenges and Considerations

While bellows sealed valves offer numerous advantages, there are some challenges and considerations:

Cost: Bellows sealed valves are typically more expensive than traditional valves due to the specialized materials and manufacturing processes involved in their production. This may make them less cost-effective for applications where leakage is not a critical concern.

Design Complexity: The design of bellows sealed valves is more complex, requiring precise fabrication and careful consideration of materials to ensure reliability under various operational conditions.

Limited Size Range: While bellows sealed valves are available in a wide range of sizes, extremely large valves may require more advanced designs or different sealing solutions due to the limitations of bellows construction.

Bellows sealed valves are an essential component in industries where leak prevention is critical. With their robust design, ability to handle extreme conditions, and minimal maintenance requirements, they offer a significant advantage over traditional valve types. By providing a tight, reliable seal, bellows sealed valves help maintain safety, environmental protection, and system efficiency across a range of high-stakes applications. While they do come at a higher initial cost, the long-term benefits of reduced leakage, improved safety, and decreased maintenance make them a valuable investment in industries with stringent sealing requirements.