BELLOWS SEALED GATE VALVE MANUFACTURER

Design Standards and Compliance

This gate valve is manufactured in accordance with API standards and designed to meet the pressure-temperature requirements of ASME B16.34, ensuring safe operation under demanding conditions. The flanged end connections conform to ASME B16.5, allowing easy installation and compatibility with standard piping systems. Testing and inspection typically comply with API 598, guaranteeing pressure integrity and seat tightness.

Body and Bonnet Construction

The valve body and bonnet are produced from ASTM A216 WCB carbon steel, a material well known for its excellent mechanical strength, toughness, and cost-effectiveness in moderate to high-temperature services. WCB carbon steel provides reliable performance in temperatures up to approximately 425°C, making it suitable for steam, oil, gas, and general industrial fluids.

The flange end design ensures rigid pipeline connection, superior sealing performance, and ease of maintenance in larger pipe sizes. The robust wall thickness and reinforced bonnet structure enhance pressure containment and operational safety.

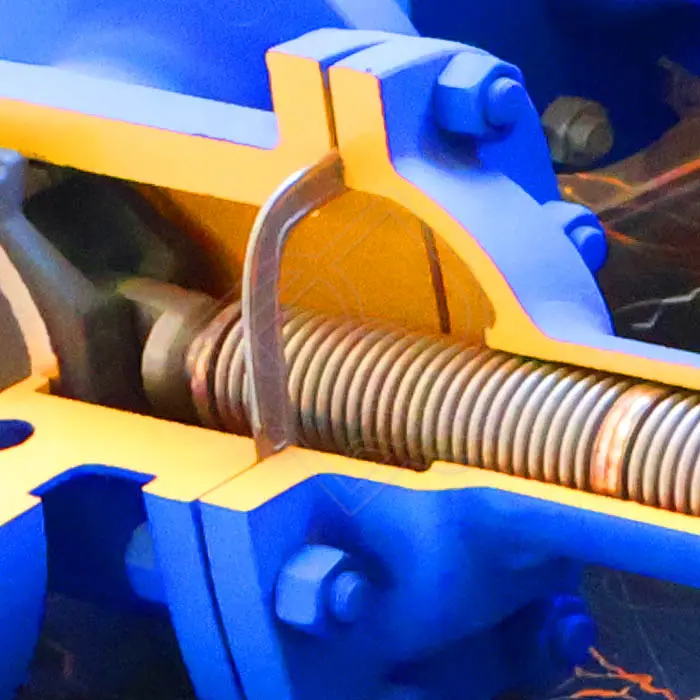

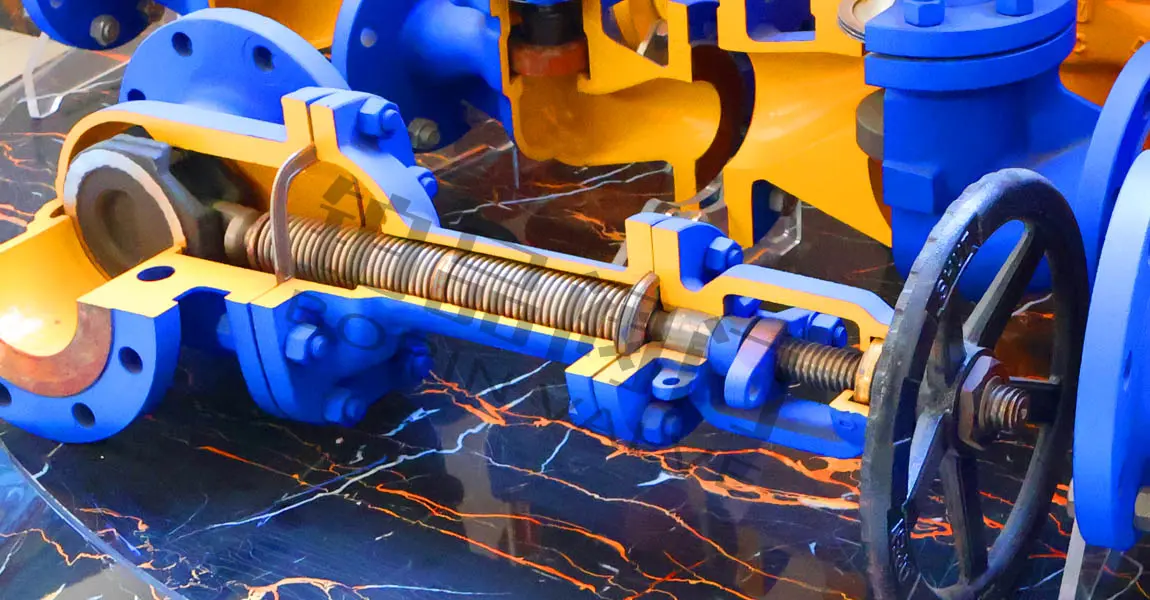

Bellows Sealing System

The defining feature of this valve is its metallic bellows seal, which provides a hermetic barrier between the process fluid and the atmosphere. The bellows is typically manufactured from stainless steel, designed to withstand repeated stem movements and thermal cycling without fatigue failure.

Unlike conventional packing-only valves, the bellows sealed design completely eliminates stem leakage, even under high temperature, high pressure, or toxic media conditions. For added safety, a backup packing arrangement is usually incorporated above the bellows, offering secondary sealing in the unlikely event of bellows failure. This dual sealing concept significantly enhances operational reliability and environmental protection.

Gate and Seat Design

The valve utilizes a wedge gate design, ensuring tight shut-off and stable operation across a wide range of pressures. The gate and seat rings are precision-machined to achieve excellent sealing performance with minimal operating torque. Depending on application requirements, the seating surfaces may be hard-faced with wear-resistant alloys to improve resistance to erosion, corrosion, and galling.

This gate valve is designed primarily for on/off service, providing full bore flow with minimal pressure drop when fully open. The straight-through flow path reduces turbulence and minimizes energy loss, which is particularly important in large-diameter pipelines.

Stem and Operating Mechanism

The stem is typically made from stainless steel and features a rising stem, outside screw and yoke (OS&Y) configuration. This design allows easy visual indication of valve position and prevents stem threads from direct contact with the process fluid, extending service life.

Manual operation is standard, using a handwheel that provides smooth and controlled opening and closing. For larger sizes or higher pressure classes, gear operators or motorized actuators can be supplied to reduce operating effort and enable remote control.

Pressure Classes and Size Range

API bellows sealed gate valves manufactured to ASME B16.34 are available in a wide range of pressure classes, commonly Class 150, 300, 600, and higher, depending on design requirements. Sizes typically range from 2 inches to 24 inches or above, making them suitable for both process and utility pipelines.

Applications

This valve is ideally suited for services where leak-free performance is critical, including:

Steam and condensate systems

Thermal oil and heat transfer fluids

Toxic, hazardous, or expensive media

Petrochemical and refinery processes

Power plants and industrial utilities

The bellows sealed construction makes it particularly valuable in applications where environmental regulations and workplace safety standards demand zero emission performance.

Advantages

Key advantages of the API ASME B16.34 A216 WCB bellows sealed gate valve include:

- Zero stem leakage and emission-free operation

- Extended service life compared to conventional packed valves

- Reduced maintenance and lower lifecycle costs

- Reliable performance under high temperature and pressure

- Full bore design with minimal pressure loss