0102030405

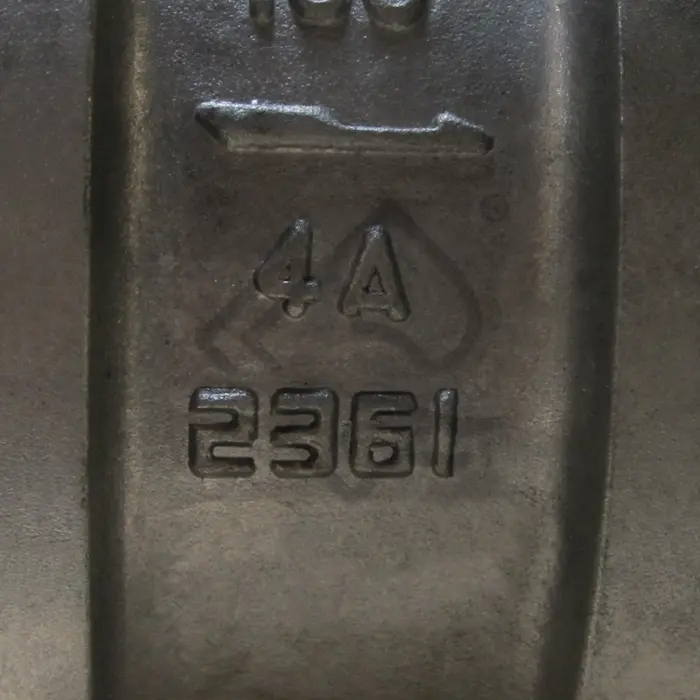

ASTM A890 Grade 4A 5A Duplex Stainless Steel Retainerless Design Dual Plate Check Valve

Material: ASTM A890 Grade 4A Duplex Stainless Steel

ASTM A890 Grade 4A is a cast duplex stainless steel equivalent to wrought UNS S31803/S32205 (commonly known as 2205 duplex). Its microstructure consists of a balanced mixture of austenite and ferrite phases, providing a unique combination of properties that surpass conventional austenitic stainless steels such as CF8 or CF8M.

Grade 4A offers high yield and tensile strength, typically about twice that of standard austenitic stainless steel. This allows for thinner sections and lighter valve bodies while maintaining high pressure ratings. In addition, its excellent resistance to pitting, crevice corrosion, stress corrosion cracking, and erosion corrosion makes it especially suitable for chloride-containing environments, seawater systems, and aggressive process fluids. These characteristics significantly extend valve service life and reduce maintenance costs.

Dual Plate Check Valve Design

The dual plate check valve, also known as a double door or split disc check valve, uses two semi-circular plates hinged on a central shaft. During forward flow, the plates open smoothly and evenly, offering minimal resistance and low pressure drop. When flow decreases or reverses, the plates close rapidly under the combined action of reverse flow and spring force, preventing backflow and reducing the risk of water hammer.

Compared with traditional swing check valves, dual plate designs are more compact, lighter, and faster acting. This makes them ideal for high-velocity flow systems and installations where space and weight are critical considerations.

Compared with traditional swing check valves, dual plate designs are more compact, lighter, and faster acting. This makes them ideal for high-velocity flow systems and installations where space and weight are critical considerations.

Retainerless Construction

A key feature of this valve is its retainerless design. Conventional dual plate check valves often use external retainers, plugs, or bolting to secure internal hinge pins. These external components can become potential leakage paths and are susceptible to corrosion, especially in harsh environments.

In a retainerless design, the hinge pin retention mechanism is fully internal. There are no external plugs or penetrations through the valve body. This design enhances pressure integrity, eliminates external leakage points, and improves overall safety. It is particularly beneficial in offshore platforms, subsea systems, and hazardous fluid services where zero external leakage is critical.

In a retainerless design, the hinge pin retention mechanism is fully internal. There are no external plugs or penetrations through the valve body. This design enhances pressure integrity, eliminates external leakage points, and improves overall safety. It is particularly beneficial in offshore platforms, subsea systems, and hazardous fluid services where zero external leakage is critical.

Compact Wafer-Type Body

ASTM A890 4A duplex stainless steel retainerless dual plate check valves are typically supplied in wafer-type construction, allowing installation between standard flanges. The compact face-to-face dimension reduces piping space requirements and overall system weight. This design also simplifies handling, transportation, and installation, especially in large-diameter pipelines.

The wafer body design ensures proper alignment between flanges and provides uniform load distribution across the gasket surfaces. Despite its compact size, the valve maintains excellent structural integrity due to the high strength of duplex stainless steel.

The wafer body design ensures proper alignment between flanges and provides uniform load distribution across the gasket surfaces. Despite its compact size, the valve maintains excellent structural integrity due to the high strength of duplex stainless steel.

Spring-Assisted Fast Closure

Most retainerless dual plate check valves incorporate stainless steel or duplex alloy springs that assist in rapid disc closure. The spring mechanism ensures that the plates begin closing as soon as forward flow diminishes, even before flow reversal occurs. This fast response minimizes slam, reduces pressure surges, and protects downstream equipment such as pumps, compressors, and meters.

Spring-assisted closure is particularly advantageous in vertical piping systems and low-pressure applications where gravity alone may not be sufficient to ensure reliable disc operation.

Spring-assisted closure is particularly advantageous in vertical piping systems and low-pressure applications where gravity alone may not be sufficient to ensure reliable disc operation.

Sealing and Performance

The valve typically features metal-to-metal or soft-seated sealing, depending on service requirements. For high-temperature or abrasive services, metal-to-metal seating provides durability and resistance to wear. For low-pressure or tight shutoff applications, resilient seats such as PTFE or reinforced polymers can be used to achieve excellent sealing performance.

The smooth internal profile of the dual plate design promotes streamlined flow and reduces turbulence, contributing to lower pressure loss and improved energy efficiency across the system.

The smooth internal profile of the dual plate design promotes streamlined flow and reduces turbulence, contributing to lower pressure loss and improved energy efficiency across the system.

Standards and Compliance

ASTM A890 Grade 4A duplex stainless steel retainerless dual plate check valves are commonly designed and manufactured in accordance with international standards such as API 594, API 6D, ASME B16.34, and ASME B16.10. Pressure ratings typically conform to ASME Class 150, 300, 600, and higher upon request.

Valves can be tested according to API 598 or ISO 5208 to ensure pressure integrity and reliable sealing performance. Optional certifications, such as NACE MR0175 / ISO 15156 compliance, are available for sour service applications.

Valves can be tested according to API 598 or ISO 5208 to ensure pressure integrity and reliable sealing performance. Optional certifications, such as NACE MR0175 / ISO 15156 compliance, are available for sour service applications.

Applications

Thanks to their robust construction and corrosion resistance, these valves are widely used in seawater cooling systems, desalination plants, offshore oil and gas platforms, chemical processing units, pulp and paper mills, and power plants. Their compact size and lightweight design make them especially suitable for retrofit projects and space-constrained installations.

Conclusion

ASTM A890 Grade 4A duplex stainless steel retainerless design dual plate check valves offer an optimal balance of strength, corrosion resistance, compactness, and operational reliability. By eliminating external retainers and utilizing a fast-acting dual plate mechanism, these valves provide enhanced safety, reduced maintenance, and long service life in severe operating conditions. They represent a highly efficient and dependable solution for modern industrial piping systems where performance and durability are paramount.