0102030405

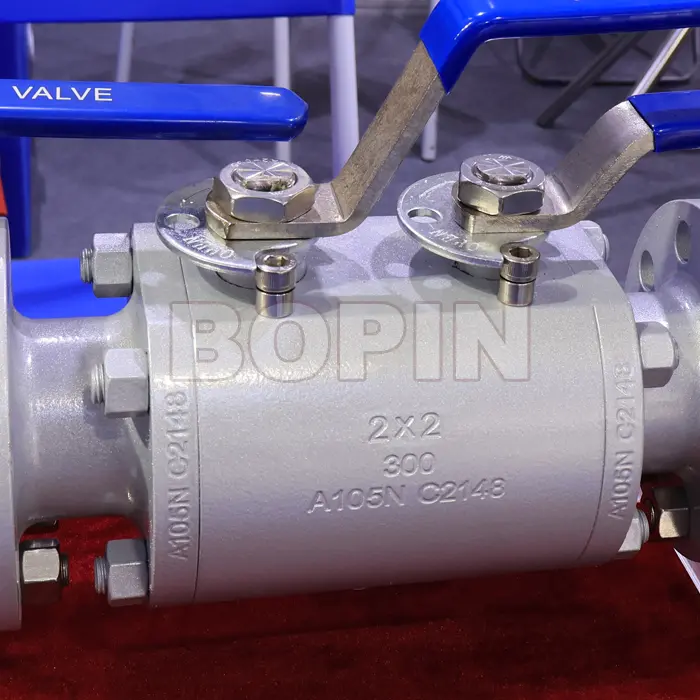

API Forged Steel Trunnion Mounted Double Block and Bleed (DBB) Ball Valve

Overview of API 6D and DBB Ball Valve Configuration

API 6D Standard

The American Petroleum Institute (API) is a trade association that sets industry standards for the oil and gas sector. API 6D specifically defines the requirements for pipeline valves used in the transmission of petroleum products and natural gas. Valves certified to API 6D are designed to handle extreme pressures, temperatures, and chemical environments, ensuring safe and efficient operation in critical pipeline applications.

The API Forged Steel Trunnion Mounted DBB Ball Valve is designed to meet these stringent API 6D standards, guaranteeing performance, reliability, and durability in the most demanding conditions.

DBB Ball Valve Configuration

The Double Block and Bleed (DBB) valve configuration refers to a design that incorporates two sealing mechanisms to block flow in both directions, combined with a dedicated bleed valve that allows the space between the two sealing elements to be vented or bled to the atmosphere. This functionality is critical in preventing hazardous leaks and ensuring safe isolation of sections of the pipeline for maintenance or inspection.

Double Block: The valve provides two separate seals in series, offering two barriers to flow in each direction.

Bleed: A bleed valve is provided to vent any trapped pressure between the seals, allowing for safe maintenance or inspection.

In a DBB Ball Valve, these features make the valve suitable for high-risk environments where safety, integrity, and pressure control are paramount.

The American Petroleum Institute (API) is a trade association that sets industry standards for the oil and gas sector. API 6D specifically defines the requirements for pipeline valves used in the transmission of petroleum products and natural gas. Valves certified to API 6D are designed to handle extreme pressures, temperatures, and chemical environments, ensuring safe and efficient operation in critical pipeline applications.

The API Forged Steel Trunnion Mounted DBB Ball Valve is designed to meet these stringent API 6D standards, guaranteeing performance, reliability, and durability in the most demanding conditions.

DBB Ball Valve Configuration

The Double Block and Bleed (DBB) valve configuration refers to a design that incorporates two sealing mechanisms to block flow in both directions, combined with a dedicated bleed valve that allows the space between the two sealing elements to be vented or bled to the atmosphere. This functionality is critical in preventing hazardous leaks and ensuring safe isolation of sections of the pipeline for maintenance or inspection.

Double Block: The valve provides two separate seals in series, offering two barriers to flow in each direction.

Bleed: A bleed valve is provided to vent any trapped pressure between the seals, allowing for safe maintenance or inspection.

In a DBB Ball Valve, these features make the valve suitable for high-risk environments where safety, integrity, and pressure control are paramount.

Key Features of the API Forged Steel Trunnion Mounted DBB Ball Valve

1. Forged Steel Construction

The construction of the valve body and other critical components in forged steel offers several benefits:

Strength and Durability: Forged steel is more robust than cast steel, providing better strength, fatigue resistance, and improved structural integrity. This is crucial for handling the high pressures and forces often encountered in oil and gas applications.

Corrosion Resistance: Forged steel valves are highly resistant to corrosion, making them ideal for use in harsh, chemically aggressive environments, such as offshore platforms or deepwater drilling operations.

Longer Service Life: The superior mechanical properties of forged steel translate to enhanced performance and longer operational life, reducing downtime and maintenance costs.

The construction of the valve body and other critical components in forged steel offers several benefits:

Strength and Durability: Forged steel is more robust than cast steel, providing better strength, fatigue resistance, and improved structural integrity. This is crucial for handling the high pressures and forces often encountered in oil and gas applications.

Corrosion Resistance: Forged steel valves are highly resistant to corrosion, making them ideal for use in harsh, chemically aggressive environments, such as offshore platforms or deepwater drilling operations.

Longer Service Life: The superior mechanical properties of forged steel translate to enhanced performance and longer operational life, reducing downtime and maintenance costs.

Trunnion Mounted Design

A trunnion-mounted ball valve features a ball that is supported by trunnions (pins) at both the top and bottom. This design offers several advantages over floating ball valves:

Lower Torque: The trunnion-mounted design reduces the friction between the ball and valve body, leading to reduced torque requirements during valve operation. This makes the valve easier to operate, even in larger sizes.

Improved Pressure Handling: The trunnions help distribute the pressure load evenly across the ball, allowing the valve to handle higher pressure differentials without excessive wear or failure.

Stability: The trunnion-mounted ball remains stable and centered within the valve, even at higher pressures or flow rates, ensuring reliable performance.

Lower Torque: The trunnion-mounted design reduces the friction between the ball and valve body, leading to reduced torque requirements during valve operation. This makes the valve easier to operate, even in larger sizes.

Improved Pressure Handling: The trunnions help distribute the pressure load evenly across the ball, allowing the valve to handle higher pressure differentials without excessive wear or failure.

Stability: The trunnion-mounted ball remains stable and centered within the valve, even at higher pressures or flow rates, ensuring reliable performance.

Double Block and Bleed (DBB) Functionality

The DBB configuration is critical for safety and isolation in high-risk industrial environments. It provides:

Double Sealing: With two independent sealing elements, the valve offers higher leak-tightness and reliability compared to single-seal designs.

Pressure Relief: The bleed valve provides a safe means of venting trapped pressure between the seals, which can be critical for maintenance operations or in the event of a pressure spike in the system.

Increased Safety: The DBB configuration is especially important in applications where the integrity of the pipeline must be maintained even under extreme conditions, such as in hazardous fluid transport.

Double Sealing: With two independent sealing elements, the valve offers higher leak-tightness and reliability compared to single-seal designs.

Pressure Relief: The bleed valve provides a safe means of venting trapped pressure between the seals, which can be critical for maintenance operations or in the event of a pressure spike in the system.

Increased Safety: The DBB configuration is especially important in applications where the integrity of the pipeline must be maintained even under extreme conditions, such as in hazardous fluid transport.

Applications of the API Forged Steel Trunnion Mounted DBB Ball Valve

The API Forged Steel Trunnion Mounted DBB Ball Valve is used across several high-pressure, high-risk applications, including:

Oil and Gas Industry: These valves are commonly found in upstream (production) and downstream (refining and distribution) operations, where they are used to isolate pipelines for maintenance, protect against fluid leaks, and regulate flow.

Chemical and Petrochemical Plants: The DBB ball valve is suitable for applications where chemical processes require high safety standards, including the transport and processing of flammable or toxic fluids.

Offshore and Subsea Operations: The high pressure and corrosive environments of offshore platforms make these valves essential for ensuring pipeline safety and integrity, especially in deepwater applications.

Power Generation: In power plants, particularly those using steam or gas turbines, DBB ball valves are used to isolate sections of the pipeline for maintenance while preventing hazardous fluid leaks.

Mining and Metallurgy: In mining operations, DBB valves are used to control the flow of slurry and other materials under high pressure, offering the reliability needed for continuous operations.

Oil and Gas Industry: These valves are commonly found in upstream (production) and downstream (refining and distribution) operations, where they are used to isolate pipelines for maintenance, protect against fluid leaks, and regulate flow.

Chemical and Petrochemical Plants: The DBB ball valve is suitable for applications where chemical processes require high safety standards, including the transport and processing of flammable or toxic fluids.

Offshore and Subsea Operations: The high pressure and corrosive environments of offshore platforms make these valves essential for ensuring pipeline safety and integrity, especially in deepwater applications.

Power Generation: In power plants, particularly those using steam or gas turbines, DBB ball valves are used to isolate sections of the pipeline for maintenance while preventing hazardous fluid leaks.

Mining and Metallurgy: In mining operations, DBB valves are used to control the flow of slurry and other materials under high pressure, offering the reliability needed for continuous operations.

Benefits of the API Forged Steel Trunnion Mounted DBB Ball Valve

Enhanced Safety: The DBB configuration offers extra layers of safety by ensuring that the pipeline is completely isolated, reducing the risk of leaks and hazardous exposure to chemicals or gas.

Higher Operational Efficiency:The valve’s ability to be operated remotely (using electrical actuation) improves operational efficiency, reduces downtime, and ensures smooth system operation.

Cost-Effective Maintenance: The bleed feature allows safe venting of trapped pressure, enabling easier and safer maintenance. The valve's durability also reduces the frequency of replacement or repair.

Versatile Use: These valves are suitable for a wide range of fluids, including gases, liquids, and slurries, making them ideal for use in multiple industries.

Compliance with Standards: Meeting API 6D standards ensures that the valve is manufactured according to the highest industry standards, providing peace of mind regarding its reliability and performance.

Higher Operational Efficiency:The valve’s ability to be operated remotely (using electrical actuation) improves operational efficiency, reduces downtime, and ensures smooth system operation.

Cost-Effective Maintenance: The bleed feature allows safe venting of trapped pressure, enabling easier and safer maintenance. The valve's durability also reduces the frequency of replacement or repair.

Versatile Use: These valves are suitable for a wide range of fluids, including gases, liquids, and slurries, making them ideal for use in multiple industries.

Compliance with Standards: Meeting API 6D standards ensures that the valve is manufactured according to the highest industry standards, providing peace of mind regarding its reliability and performance.