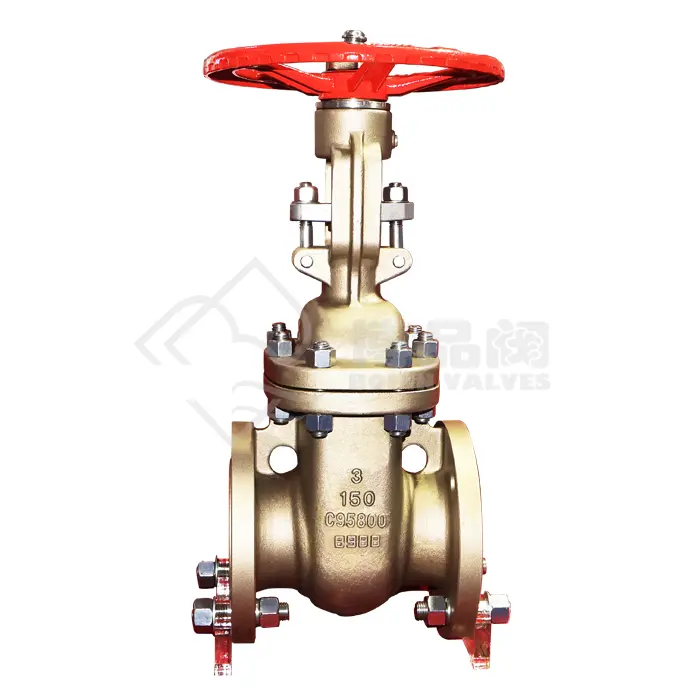

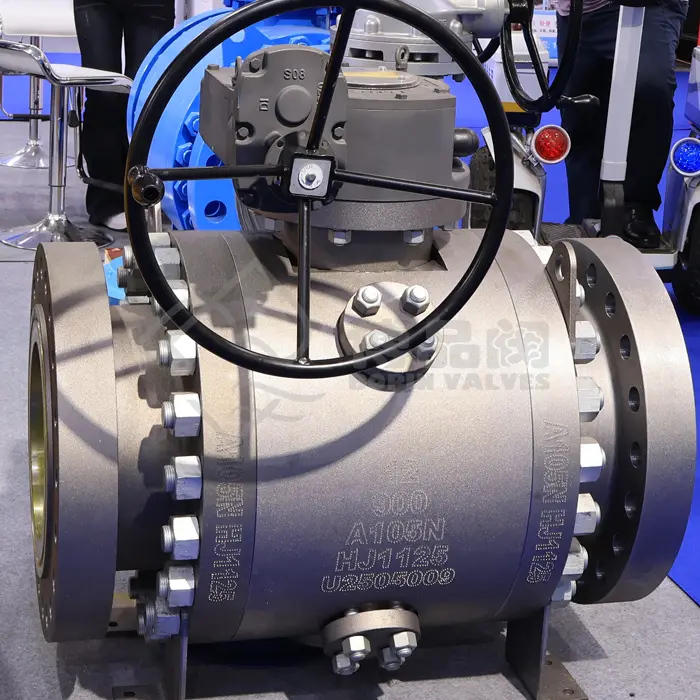

API 6D SIDE ENTRY FLANGED GEAR OPERATED FORGED STEEL BALL VALVE

Overview of the API 6D Standard

The API 6D standard is a set of guidelines and specifications for pipeline valves used in petroleum and natural gas industries. API 6D valves are designed to perform efficiently under extreme conditions, ensuring safe and secure fluid control throughout the pipeline infrastructure.

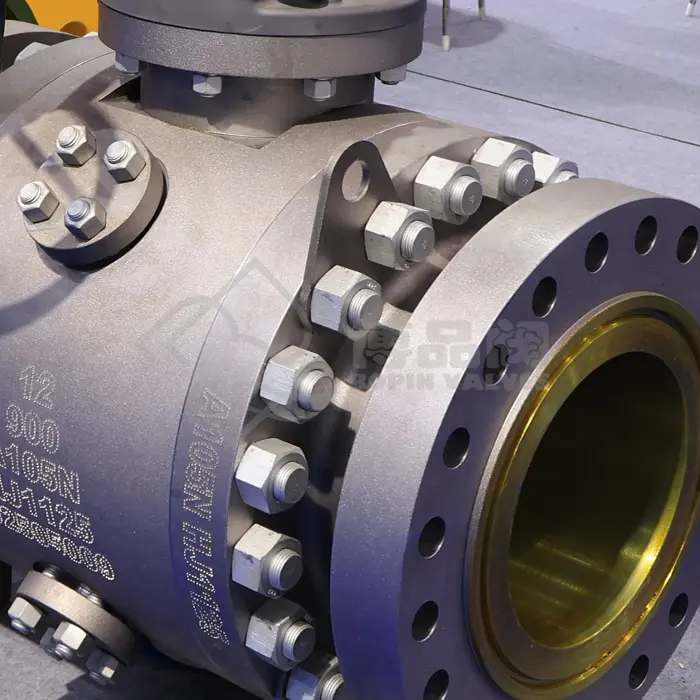

API 6D valves must meet specific criteria for material composition, pressure ratings, valve design, operation, testing, and performance, ensuring they can handle the rigorous demands of high-pressure environments. The Side Entry Flanged Gear Operated Forged Steel Ball Valve is one such valve that adheres to these strict standards.

Key Features of the API 6D Side Entry Flanged Gear Operated Forged Steel Ball Valve

Side Entry Design: The side entry design of the valve enables the ball to be inserted and removed from the valve body from the side, as opposed to top-entry designs. This feature is particularly beneficial for applications that require frequent maintenance, as it simplifies the disassembly and reassembly of the valve without the need to remove it from the pipeline.

Flanged Connections: The valve is equipped with flanged connections, which provide a secure and leak-proof seal when the valve is installed into the pipeline. The flanges adhere to industry-standard dimensions, typically ASME B16.5, ensuring compatibility with a wide range of pipeline systems.

Forged Steel Construction: The valve body and other critical components are made from forged steel, which is known for its high strength, durability, and resistance to fatigue and wear. Forged steel offers superior mechanical properties compared to cast materials, making the valve more resistant to pressure, corrosion, and mechanical stresses.

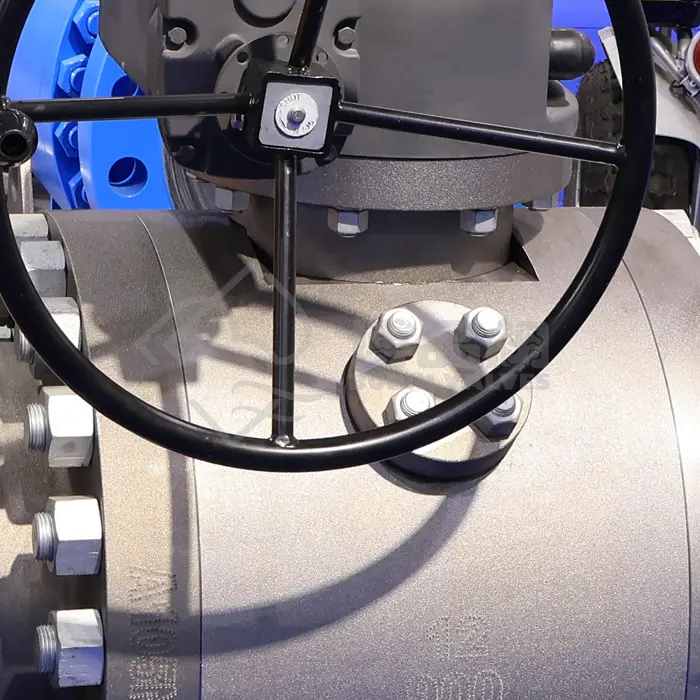

Gear Operated Actuation: The gear-operated mechanism is used to turn the valve’s stem and ball, providing smooth operation even in high-torque applications. This feature is particularly advantageous in large valves or systems with high operating pressures, where manual operation may not be feasible. Gear operators also offer precision control, which is crucial for maintaining desired flow rates in process systems.

Ball Valve Mechanism: The ball valve design utilizes a spherical ball with a hole through its center to control the flow of fluids. When the valve is open, the hole in the ball is aligned with the pipeline, allowing flow. When the valve is closed, the ball rotates 90° to block the flow. This design offers quick and reliable on-off control of the flow.

High Pressure and Temperature Ratings: Forged steel ball valves typically have a higher pressure and temperature tolerance compared to other materials, making them ideal for demanding applications in industries such as oil and gas, power generation, and chemical processing.

Leak Tightness: The valve is designed to prevent leakage when fully closed, offering exceptional sealing capabilities. Stem packing and ball seals are engineered to handle high-pressure systems and ensure tight sealing even in extreme operating conditions.

Manual and Automated Control: The valve can be operated manually using the gear mechanism, or it can be fitted with actuators for automated operation. This flexibility makes the valve suitable for a wide range of applications, from manual control in smaller systems to remote and automated control in large-scale industrial processes.

Design Principles of API 6D Side Entry Flanged Gear Operated Forged Steel Ball Valve

Material Selection: The materials used in the construction of the valve must be selected for their ability to withstand harsh operating conditions. Forged steel is typically used for the body, while chrome-molybdenum alloys or stainless steel may be used for internal components, depending on the application. The materials must also meet the corrosion resistance and strength requirements specified in the API 6D standard.

Flow Control: The design of the ball, seat, and stem is optimized to ensure efficient flow control with minimal turbulence and pressure loss. The ball should have a smooth, polished surface to reduce friction and wear, which also contributes to the valve’s longevity.

Seal Design: The seal between the valve body and the ball is critical for leak prevention. PTFE (polytetrafluoroethylene) or RPTFE (reinforced PTFE) materials are often used for the seat seals due to their excellent chemical resistance and low friction properties.

Durability: The valve is designed for longevity, with components that are resistant to abrasion, corrosion, and thermal degradation. The gear mechanism is designed for easy operation over thousands of cycles without compromising performance.

Pressure and Temperature Ratings: The valve is designed to handle high pressure and temperature, as specified in the API 6D standard. It should be capable of withstanding the specified test pressures (usually up to 1.5x the design pressure) and high-temperature environments.

Safety Features: API 6D valves are equipped with safety features, such as anti-blowout stems and locking devices, to prevent accidental valve operation and ensure safe installation and use in high-risk environments.

Applications of API 6D Side Entry Flanged Gear Operated Forged Steel Ball Valve

The API 6D Side Entry Flanged Gear Operated Forged Steel Ball Valve is used in a wide range of industries where high-pressure and high-temperature conditions are common. Some of the most prominent applications include:

Oil and Gas Industry: API 6D ball valves are widely used in upstream and downstream oil and gas operations, including exploration, production, refining, and transportation. They are used to control the flow of crude oil, natural gas, and refined products in pipelines, storage tanks, and processing units.

Chemical and Petrochemical Industries: In chemical plants, these valves control the flow of various liquids and gases, including corrosive and high-temperature chemicals. The forged steel construction and reliable sealing mechanisms ensure that the valves can handle the demanding conditions in these industries.

Power Generation: Ball valves are critical in power plants for controlling the flow of steam, water, and other fluids in boilers, turbines, and cooling systems. The valve’s ability to handle high temperatures and pressures makes it ideal for steam control in thermal power plants.

Water Treatment: API 6D ball valves are also used in water treatment plants for controlling the flow of water and chemicals, such as disinfectants and coagulants, during the purification process. The valves’ ability to offer precise control makes them suitable for various stages of water treatment.

Pipelines: These valves are frequently employed in pipeline systems to isolate sections of the pipeline, especially in cases where the pipeline needs to be shut down for maintenance or repair. Their side-entry design allows for easy replacement and maintenance without removing the valve from the line.

Advantages of API 6D Side Entry Flanged Gear Operated Forged Steel Ball Valve

High Reliability and Durability: The forged steel construction ensures that the valve can withstand high pressures and temperatures without failure, reducing the likelihood of unplanned shutdowns and extending the valve’s service life.

Minimal Maintenance: The side entry design allows for quick and easy maintenance, as the valve components can be accessed and replaced without having to remove the entire valve from the pipeline. This leads to reduced downtime and maintenance costs.

Precise Flow Control: The gear-operated mechanism allows for fine control of the valve position, ensuring precise regulation of the flow rate. This is essential in applications where flow control is critical, such as chemical processing or power generation.

Leak Prevention: The valve’s design ensures excellent leak-tight performance, preventing hazardous fluids from escaping into the environment. This is particularly important in industries such as oil and gas, where leakage can lead to environmental contamination.

Versatility: The valve can be operated manually or automated, offering flexibility for different operational needs. The ability to handle a wide range of pressures and temperatures makes it suitable for a variety of industries.

Maintenance Considerations

Regular Inspection: Inspecting the valve for wear and tear, especially on the ball and seat surfaces, is essential to ensure that it remains leak-tight and functional. Regular inspections can prevent issues such as valve seizure or leakage.

Lubrication: The gear mechanism and stem should be regularly lubricated to prevent friction and ensure smooth operation. Proper lubrication helps prevent premature wear and failure of the valve.

Seal Replacement: Over time, the seals may degrade due to exposure to high temperatures, pressures, or chemicals. Replacing the seals during scheduled maintenance can extend the valve’s service life and maintain optimal performance.

Actuator Maintenance: If the valve is equipped with an actuator, it’s important to maintain and test the actuator to ensure reliable automated operation. Regular testing and calibration ensure that the actuator responds correctly to control signals.