0102030405

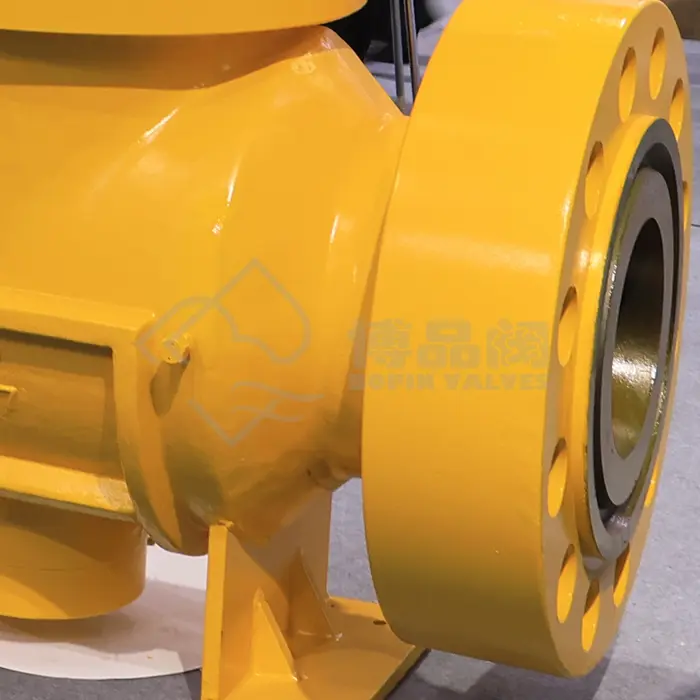

API 6D Cast Steel Top Entry Ball Valve

Construction and Materials

The API 6D Cast Steel Top Entry Ball Valve is typically made from cast steel, which offers a robust and durable solution for high-pressure and high-temperature environments. Cast steel is favored for its excellent strength, resistance to corrosion, and ability to withstand harsh operating conditions. The valve's body, ball, and other internal components are precisely crafted from this material to ensure reliability and longevity.

The "top entry" design refers to the method by which the valve’s internal components, including the ball and seats, are accessed for maintenance or replacement. This design offers several advantages over traditional side-entry valves, including easier maintenance, reduced downtime, and the ability to replace parts without removing the valve from the pipeline.

The "top entry" design refers to the method by which the valve’s internal components, including the ball and seats, are accessed for maintenance or replacement. This design offers several advantages over traditional side-entry valves, including easier maintenance, reduced downtime, and the ability to replace parts without removing the valve from the pipeline.

Features of the API 6D Cast Steel Top Entry Ball Valve

Top Entry Design:

The top entry design allows for internal repairs and maintenance without disassembling the entire valve from the pipeline. This feature minimizes operational downtime and maintenance costs, making it a preferred choice for critical operations where pipeline access is limited or difficult.

Ball Valve Operation:

The valve uses a spherical ball with a hole in the center, which rotates to control the flow of fluid. When the ball’s hole is aligned with the pipeline, the fluid flows; when it’s perpendicular to the pipeline, the flow is stopped. This simple and reliable mechanism provides quick and accurate flow control.

High Pressure and Temperature Tolerance:

API 6D Cast Steel Ball Valves are designed to handle extreme pressure and temperature conditions. These valves are ideal for high-pressure gas pipelines, as well as steam and other high-temperature applications.

Leakage Prevention:

These valves are engineered with tight sealing mechanisms, ensuring minimal leakage during operation. The ball and seat materials are selected to provide long-lasting sealing performance even under challenging conditions.

Corrosion and Erosion Resistance:

The choice of cast steel and the high-quality surface finish help these valves resist the harmful effects of corrosion and erosion caused by fluid flow, particularly in aggressive media like acids, slurries, or seawater.

Durability:

API 6D Cast Steel Top Entry Ball Valves are known for their exceptional service life, which results from their solid construction and robust materials. Their resistance to wear and tear ensures long-term performance in pipeline systems.

The top entry design allows for internal repairs and maintenance without disassembling the entire valve from the pipeline. This feature minimizes operational downtime and maintenance costs, making it a preferred choice for critical operations where pipeline access is limited or difficult.

Ball Valve Operation:

The valve uses a spherical ball with a hole in the center, which rotates to control the flow of fluid. When the ball’s hole is aligned with the pipeline, the fluid flows; when it’s perpendicular to the pipeline, the flow is stopped. This simple and reliable mechanism provides quick and accurate flow control.

High Pressure and Temperature Tolerance:

API 6D Cast Steel Ball Valves are designed to handle extreme pressure and temperature conditions. These valves are ideal for high-pressure gas pipelines, as well as steam and other high-temperature applications.

Leakage Prevention:

These valves are engineered with tight sealing mechanisms, ensuring minimal leakage during operation. The ball and seat materials are selected to provide long-lasting sealing performance even under challenging conditions.

Corrosion and Erosion Resistance:

The choice of cast steel and the high-quality surface finish help these valves resist the harmful effects of corrosion and erosion caused by fluid flow, particularly in aggressive media like acids, slurries, or seawater.

Durability:

API 6D Cast Steel Top Entry Ball Valves are known for their exceptional service life, which results from their solid construction and robust materials. Their resistance to wear and tear ensures long-term performance in pipeline systems.

Applications

API 6D Cast Steel Top Entry Ball Valves are commonly used in the following industries:

Oil and Gas: For regulating the flow of oil and gas in transportation pipelines, offshore platforms, and gas processing plants.

Petrochemical: In chemical processing plants, where controlled flow of corrosive chemicals is required.

Water Treatment: For regulating the flow of water or chemicals in municipal and industrial water treatment facilities.

Power Generation: In power plants, particularly for steam and fuel gas applications, where high-pressure and high-temperature tolerances are critical.

Mining: Used in slurry pipelines, where resistance to erosion is vital.

Oil and Gas: For regulating the flow of oil and gas in transportation pipelines, offshore platforms, and gas processing plants.

Petrochemical: In chemical processing plants, where controlled flow of corrosive chemicals is required.

Water Treatment: For regulating the flow of water or chemicals in municipal and industrial water treatment facilities.

Power Generation: In power plants, particularly for steam and fuel gas applications, where high-pressure and high-temperature tolerances are critical.

Mining: Used in slurry pipelines, where resistance to erosion is vital.

Benefits

Reduced Maintenance: The top-entry feature allows for maintenance and part replacements without disrupting the pipeline system, which reduces downtime and operational costs.

Safety: These valves ensure that hazardous fluids are controlled efficiently, preventing accidental leaks or spills, which is especially important in critical infrastructure like oil pipelines and power plants.

Cost-Effectiveness: The durability and reduced maintenance needs of these valves contribute to cost savings over their lifetime. The long service life and ease of maintenance also reduce the overall cost of ownership.

Flexibility in Design: API 6D valves can be designed to suit various applications, with customized materials and configurations to meet specific client needs.

Safety: These valves ensure that hazardous fluids are controlled efficiently, preventing accidental leaks or spills, which is especially important in critical infrastructure like oil pipelines and power plants.

Cost-Effectiveness: The durability and reduced maintenance needs of these valves contribute to cost savings over their lifetime. The long service life and ease of maintenance also reduce the overall cost of ownership.

Flexibility in Design: API 6D valves can be designed to suit various applications, with customized materials and configurations to meet specific client needs.

Standards and Compliance

The API 6D specification governs the manufacturing and testing requirements for pipeline valves, ensuring they meet the highest standards of performance and safety. Compliance with this standard ensures that the valve is fit for the demanding conditions found in the oil and gas industry, as well as other high-risk applications. API 6D also includes stringent requirements for testing the valve's pressure, temperature, and sealing capabilities, ensuring reliable operation in the most challenging environments.

Additionally, these valves are often tested for leakage, pressure resistance, and flow performance according to international standards like ASME, ANSI, and ISO, further enhancing their reliability.

Additionally, these valves are often tested for leakage, pressure resistance, and flow performance according to international standards like ASME, ANSI, and ISO, further enhancing their reliability.

Maintenance and Inspection

One of the key advantages of the Top Entry design is that maintenance and inspection can be performed without removing the valve from the pipeline. The valve's top-entry feature allows technicians to access internal components, such as the ball, stem, and seats, for easy repair or replacement. This significantly reduces maintenance costs and prevents lengthy downtimes.

Routine inspection should focus on checking for valve body corrosion, wear on the ball and seats, and ensuring that seals remain intact. Additionally, regular operational testing ensures the valve continues to perform to specifications, providing a reliable shut-off and control function.

Routine inspection should focus on checking for valve body corrosion, wear on the ball and seats, and ensuring that seals remain intact. Additionally, regular operational testing ensures the valve continues to perform to specifications, providing a reliable shut-off and control function.