High-Quality API 609 Triple Offset Butterfly Valves - Top Suppliers & Manufacturers

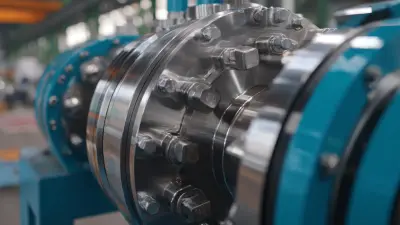

For high-quality API 609 Flange Type Triple Offset Butterfly Valves, trust our commitment to excellence and performance. As a leading manufacturer, we prioritize precision and durability, ensuring our valves operate effectively across various industrial applications. Our products are crafted to meet strict quality standards, reflecting our dedication to innovation and reliability. With a wide range of options tailored to meet your specific needs, choosing our valves means investing in superior craftsmanship and dependable performance. We are dedicated to supporting your business with the best valve solutions available.

Tips & Tricks for Api 609 Flange Type Triple Offset Butterfly Valves Service Application

When it comes to enhancing operational efficiency and reliability in fluid control systems, the API 609 flange type triple offset butterfly valves are an essential component. These innovative valves are designed for demanding applications, offering a unique combination of features that adapt seamlessly to various requirements. Understanding the intricacies of their service application can significantly boost performance and longevity. One of the key tips for maintaining these valves is to ensure proper installation, which minimizes stress on the disc and helps avoid any misalignment that could lead to operational issues. Additionally, regular inspection and maintenance are crucial. Check for signs of wear, corrosion, or malfunction, as addressing these early can prevent costly downtime. Using the right materials and specifications tailored to your operational environment, such as correct pressure ratings and sizes, is paramount. Here at BOPIN VALVE, we pride ourselves on our ability to customize valves based on unique customer requirements, ensuring they perfectly match the intended application. By investing in the right triple offset butterfly valves and adhering to best practices for their service application, global buyers can enhance system efficiency and reliability. Our expertise in designing valves that meet specific material and operational criteria sets us apart. Trust BOPIN VALVE to provide solutions that not only meet your current needs but also anticipate future challenges in your fluid control systems.

Tips & Tricks for Api 609 Flange Type Triple Offset Butterfly Valves Service Application

| Tip / Trick | Description | Frequency | Notes |

|---|---|---|---|

| Regular Inspection | Inspect valve for any signs of wear and leakage. | Quarterly | Ensure seals are intact. |

| Lubrication | Apply suitable lubricant to the shaft and seat area. | Biannually | Use non-corrosive lubricants. |

| Seat Alignment | Check and adjust seat alignment to prevent leaks. | As needed | Misalignment can cause premature wear. |

| Operating Torque Check | Monitor operating torque to ensure proper functionality. | Monthly | Over-torque can damage the valve. |

| Cleaning | Remove debris and dirt from valve exterior. | Monthly | Ensure valve operates under clean conditions. |

Comprehensive Comparison of Api 609 Flange Type Triple Offset Butterfly Valves Outperforms the Competition Your Trusted OEM Partner

E

Emily Chen

The quality of the products exceeded my expectations. The support team was extremely helpful in addressing my queries.

17 May 2025

D

David Martinez

Impressive quality! The team was quick to assist with all my questions.

10 June 2025

N

Nora Hall

The craftsmanship is top-level! Their support team was knowledgeable and very helpful.

04 June 2025

R

Robert Cooper

Impressed with the quality! The after-sales service was responsive and professional.

29 June 2025

C

Charlotte Wilson

I am extremely pleased with my order! The after-sales team was very responsive.

03 June 2025

M

Maya Taylor

I couldn’t be happier! The quality is superb, and the support is unrivaled.

30 June 2025