0102030405

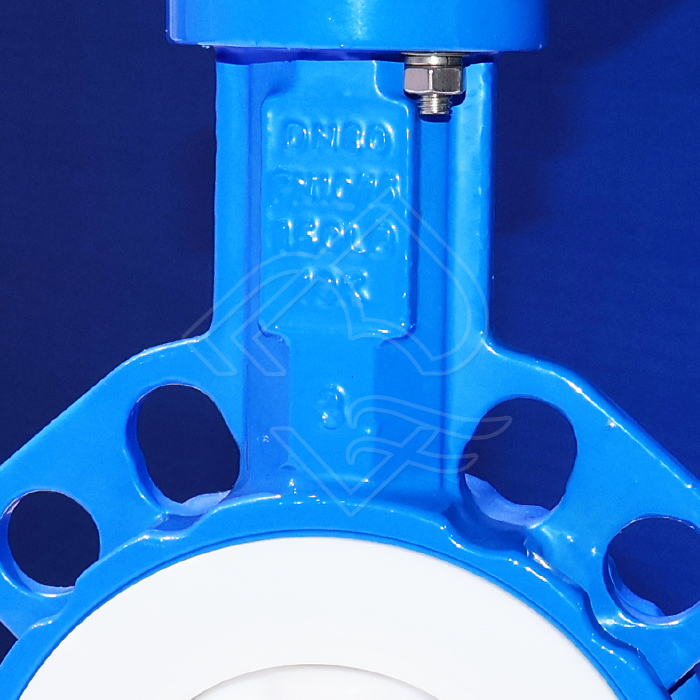

API 609 Carbon Steel Split Body Manual Type Fully PTFE Lined Wafer Type Butterfly Valve

1. Understanding the API 609 Standard

API 609 is a standard developed by the American Petroleum Institute (API) that governs the design, manufacturing, and testing of butterfly valves used in industrial applications. The API 609 standard outlines performance specifications for valves used in pipelines to regulate fluid flow. The Carbon Steel Split Body Manual Type Fully PTFE Lined Wafer Type Butterfly Valve adheres to this standard, ensuring that it meets stringent quality and safety requirements.

This particular valve configuration features a split body design, a manual actuator, and a fully PTFE (Polytetrafluoroethylene) lining, combining the durability of carbon steel with the excellent corrosion resistance of PTFE.

2. Design Features

Carbon Steel Split Body:

The valve body is constructed from carbon steel, a highly durable material that offers a good balance of strength and cost-effectiveness. The split-body design allows for easier assembly and maintenance, as the valve body is divided into two halves, which can be easily separated when servicing or replacing internal components. The carbon steel construction makes the valve suitable for a variety of medium- to high-pressure applications, providing excellent structural integrity under challenging operational conditions.

The valve body is constructed from carbon steel, a highly durable material that offers a good balance of strength and cost-effectiveness. The split-body design allows for easier assembly and maintenance, as the valve body is divided into two halves, which can be easily separated when servicing or replacing internal components. The carbon steel construction makes the valve suitable for a variety of medium- to high-pressure applications, providing excellent structural integrity under challenging operational conditions.

PTFE Lining:

The internal surfaces of the valve are coated with a fully PTFE lining, which provides excellent resistance to a wide range of chemicals, solvents, and high temperatures. PTFE, often referred to as "Teflon," is a high-performance plastic that resists corrosion, abrasion, and chemical attack, making it ideal for use in applications where the media is highly corrosive, sticky, or abrasive. The PTFE lining also helps reduce friction, which enhances the valve’s operational performance and longevity. The fully lined valve body ensures that the internal components of the valve are protected from aggressive fluids, extending the life of the valve and improving the overall system reliability.

The internal surfaces of the valve are coated with a fully PTFE lining, which provides excellent resistance to a wide range of chemicals, solvents, and high temperatures. PTFE, often referred to as "Teflon," is a high-performance plastic that resists corrosion, abrasion, and chemical attack, making it ideal for use in applications where the media is highly corrosive, sticky, or abrasive. The PTFE lining also helps reduce friction, which enhances the valve’s operational performance and longevity. The fully lined valve body ensures that the internal components of the valve are protected from aggressive fluids, extending the life of the valve and improving the overall system reliability.

Wafer Type Design:

The wafer-type valve design is compact, making it ideal for installation between flanges without the need for additional bolting or flanged connections. The wafer-style butterfly valve is lightweight, reducing the overall installation cost, and its slim design allows for easy integration into existing piping systems. It is an ideal choice for applications where space constraints are a concern.

The wafer-type valve design is compact, making it ideal for installation between flanges without the need for additional bolting or flanged connections. The wafer-style butterfly valve is lightweight, reducing the overall installation cost, and its slim design allows for easy integration into existing piping systems. It is an ideal choice for applications where space constraints are a concern.

Manual Operation:

The manual operation of this valve is typically facilitated by a handwheel, which is used to rotate the valve stem and control the butterfly disc inside the valve body. The manual operation ensures precise flow control, making it suitable for applications where the operator needs to control the flow of media accurately. While manual operation requires physical effort to operate the valve, it is reliable, cost-effective, and easy to maintain.

The manual operation of this valve is typically facilitated by a handwheel, which is used to rotate the valve stem and control the butterfly disc inside the valve body. The manual operation ensures precise flow control, making it suitable for applications where the operator needs to control the flow of media accurately. While manual operation requires physical effort to operate the valve, it is reliable, cost-effective, and easy to maintain.

Butterfly Disc:

The valve features a butterfly disc, a flat circular plate that is mounted on a shaft within the valve body. This disc rotates to regulate fluid flow through the valve. In a fully open position, the disc aligns with the flow path, allowing maximum flow; when the valve is closed, the disc blocks the flow, preventing media from passing through.

The valve features a butterfly disc, a flat circular plate that is mounted on a shaft within the valve body. This disc rotates to regulate fluid flow through the valve. In a fully open position, the disc aligns with the flow path, allowing maximum flow; when the valve is closed, the disc blocks the flow, preventing media from passing through.

Sealing Mechanism:

The sealing mechanism of this valve is enhanced by the PTFE liner, which provides a reliable seal against leakage. The liner ensures that the valve can handle a wide range of fluid types while maintaining a tight seal even under high pressure.

The sealing mechanism of this valve is enhanced by the PTFE liner, which provides a reliable seal against leakage. The liner ensures that the valve can handle a wide range of fluid types while maintaining a tight seal even under high pressure.

3. Key Applications

API 609 Carbon Steel Split Body Manual Type Fully PTFE Lined Wafer Type Butterfly Valve is used in a wide variety of industries where control over the flow of aggressive, corrosive, or viscous fluids is required. Some of the key applications include:

Chemical and Petrochemical Industries:

The chemical industry often involves the use of highly reactive chemicals that can corrode traditional valve materials. The PTFE lining in this valve provides an effective barrier against these corrosive substances, making it a crucial component in handling acids, bases, solvents, and other aggressive chemicals. The wafer-style design allows the valve to be easily integrated into chemical processing systems where space constraints are a concern.

The chemical industry often involves the use of highly reactive chemicals that can corrode traditional valve materials. The PTFE lining in this valve provides an effective barrier against these corrosive substances, making it a crucial component in handling acids, bases, solvents, and other aggressive chemicals. The wafer-style design allows the valve to be easily integrated into chemical processing systems where space constraints are a concern.

Pharmaceutical Industry:

In the pharmaceutical industry, strict sanitary conditions are required to maintain product integrity and prevent contamination. The PTFE lining ensures that the valve does not leach any substances into the media, making it ideal for applications in drug manufacturing, sterilization systems, and fluid transfer.

In the pharmaceutical industry, strict sanitary conditions are required to maintain product integrity and prevent contamination. The PTFE lining ensures that the valve does not leach any substances into the media, making it ideal for applications in drug manufacturing, sterilization systems, and fluid transfer.

Water and Wastewater Treatment:

The valve is also extensively used in water and wastewater treatment facilities. It can handle water treatment chemicals and sludge transfer applications. The PTFE lining prevents corrosion from aggressive substances present in wastewater systems, ensuring the valve operates reliably over time.

The valve is also extensively used in water and wastewater treatment facilities. It can handle water treatment chemicals and sludge transfer applications. The PTFE lining prevents corrosion from aggressive substances present in wastewater systems, ensuring the valve operates reliably over time.

Food and Beverage Processing:

The PTFE-lined butterfly valve is also used in food and beverage processing, where sanitary standards are essential. The valve’s ability to resist contamination and maintain the purity of the product makes it suitable for controlling the flow of liquids, pulps, and food-grade chemicals in processing lines.

The PTFE-lined butterfly valve is also used in food and beverage processing, where sanitary standards are essential. The valve’s ability to resist contamination and maintain the purity of the product makes it suitable for controlling the flow of liquids, pulps, and food-grade chemicals in processing lines.

Pulp and Paper Industry:

In the pulp and paper industry, the PTFE-lined valve handles the highly abrasive and corrosive chemicals used in pulp preparation, bleaching, and processing. The durability of the carbon steel body, combined with the PTFE lining, ensures long-lasting performance in these demanding applications.

In the pulp and paper industry, the PTFE-lined valve handles the highly abrasive and corrosive chemicals used in pulp preparation, bleaching, and processing. The durability of the carbon steel body, combined with the PTFE lining, ensures long-lasting performance in these demanding applications.

4. Advantages of PTFE Lined Butterfly Valves

Corrosion Resistance:

The most significant advantage of PTFE-lined butterfly valves is their resistance to corrosion. The PTFE lining protects the valve body from aggressive chemicals, salts, acids, and bases, ensuring a longer lifespan compared to traditional unlined valves.

The most significant advantage of PTFE-lined butterfly valves is their resistance to corrosion. The PTFE lining protects the valve body from aggressive chemicals, salts, acids, and bases, ensuring a longer lifespan compared to traditional unlined valves.

Cost-Effective:

Carbon steel, used for the valve body, is a relatively low-cost material, making PTFE-lined butterfly valves an economical choice for industries needing corrosion resistance without the higher cost of exotic alloys like stainless steel or Hastelloy.

Carbon steel, used for the valve body, is a relatively low-cost material, making PTFE-lined butterfly valves an economical choice for industries needing corrosion resistance without the higher cost of exotic alloys like stainless steel or Hastelloy.

Easy Installation and Maintenance:

The wafer-type design allows for easy installation between flanges, reducing the need for additional bolting or other connections. The split-body design also facilitates easy maintenance by enabling quick access to internal components.

The wafer-type design allows for easy installation between flanges, reducing the need for additional bolting or other connections. The split-body design also facilitates easy maintenance by enabling quick access to internal components.

Precision Flow Control:

The manual operation of the valve allows for precise control over the flow of fluids. This is particularly important in applications where exact flow regulation is needed, such as in chemical dosing or pressure regulation.

The manual operation of the valve allows for precise control over the flow of fluids. This is particularly important in applications where exact flow regulation is needed, such as in chemical dosing or pressure regulation.

Space-Saving Design:

The wafer-type design is compact, which allows for installation in confined spaces where traditional flanged valves would not fit. This is a significant advantage in systems with limited space.

The wafer-type design is compact, which allows for installation in confined spaces where traditional flanged valves would not fit. This is a significant advantage in systems with limited space.

Minimal Leakage:

The PTFE lining and sealing mechanism of the valve ensure minimal leakage, even when handling highly viscous or corrosive fluids. This feature is crucial in preventing contamination and ensuring safe operations in sensitive environments.

The PTFE lining and sealing mechanism of the valve ensure minimal leakage, even when handling highly viscous or corrosive fluids. This feature is crucial in preventing contamination and ensuring safe operations in sensitive environments.

The API 609 Carbon Steel Split Body Manual Type Fully PTFE Lined Wafer Type Butterfly Valve offers a reliable, cost-effective, and durable solution for fluid control in industries requiring high corrosion resistance and precise flow regulation. Its carbon steel construction, PTFE lining, and wafer-style design make it a versatile and dependable valve for a wide range of applications, from chemical processing to wastewater treatment. The valve's ability to handle aggressive fluids, resist corrosion, and reduce maintenance requirements makes it an essential component in many industrial systems.