0102030405

API 602 COMPACT STEEL GATE VALVE

What is an API 602 Compact Steel Gate Valve?

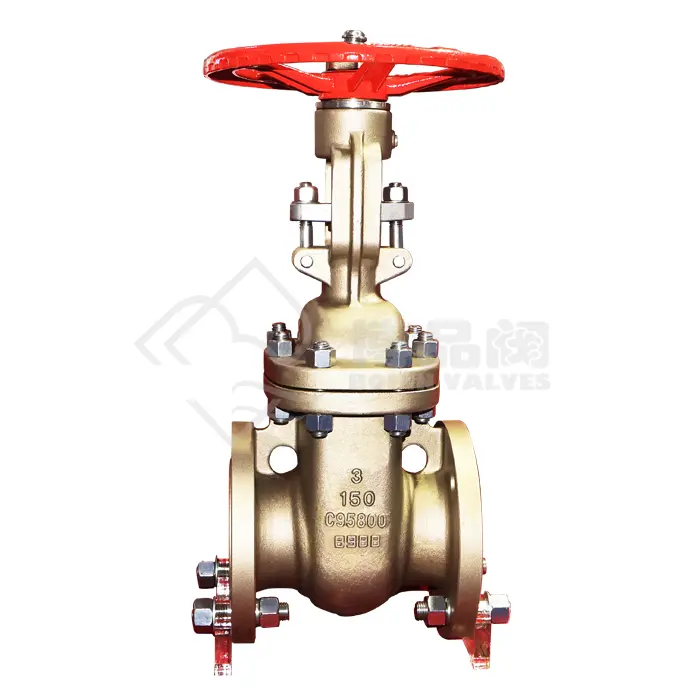

The API 602 valve is a type of gate valve, which is a valve designed to regulate or stop the flow of fluid by lifting or lowering a gate element. Unlike globe valves or ball valves, gate valves are primarily used for fully opening or fully closing a pipeline, rather than controlling the flow. The API 602 designation refers to a particular standard established by the American Petroleum Institute, which sets the technical specifications for small, compact gate valves used in high-pressure systems.

A “compact” steel gate valve means that the design of the valve is optimized to reduce its overall size while maintaining its strength and functionality. This makes it an ideal choice for installations in spaces with limited room or where weight reduction is a concern.

Design Features of the API 602 Compact Steel Gate Valve

The design of the API 602 compact steel gate valve is focused on maximizing performance, reliability, and durability. Key design features include:

Material Selection: The valve body, bonnet, and internal components are typically made from high-quality carbon steel, stainless steel, or alloy steel. This ensures the valve is resistant to corrosion and can withstand the harsh environments often found in industrial applications.

Compact Size: The “compact” aspect refers to a more streamlined construction compared to standard gate valves. This reduces the space required for installation and minimizes weight, making the valve more suitable for applications where size and weight are critical.

Gate Design: The valve uses a wedge gate, which provides a positive shutoff when the valve is closed. The gate is designed to ensure a tight seal, preventing leaks and ensuring the integrity of the pipeline.

Pressure and Temperature Ratings: API 602 valves are designed to operate in extreme pressure and temperature conditions. They typically have pressure ratings ranging from Class 150 to Class 2500 and are capable of handling high temperatures up to 1000°F (537°C), depending on the material used.

Stem Design: The valve stem is designed to provide a smooth and reliable operation, even under high pressure. It is often threaded for easy operation and repair, allowing the gate to rise or fall smoothly.

Bonnet and Seal: The bonnet houses the stem and provides a chamber where the stem can move. The bonnet also contains seals that prevent leakage from the valve body, ensuring that the valve operates efficiently without fluid loss.

Actuation: While manual operation is common, the API 602 compact steel gate valve can also be equipped with actuators for automated control in larger systems. This enables precise and remote operation, enhancing system efficiency and safety.

Advantages of the API 602 Compact Steel Gate Valve

The API 602 compact steel gate valve offers several advantages over other valve types, making it a popular choice for many industries. These advantages include:

Durability and Longevity: The high-quality materials used in the construction of the valve provide excellent resistance to corrosion, erosion, and wear, which translates into a long service life. These valves can withstand extreme environmental conditions, including exposure to aggressive chemicals, high temperatures, and high pressures.

Reduced Maintenance: The simple yet effective design of the API 602 valve reduces the need for frequent maintenance or repairs. The compact construction also minimizes the potential for damage from external factors, such as vibrations or impact.

Space Efficiency: The compact design makes this valve ideal for installations in areas where space is limited, such as offshore rigs or smaller pipeline systems. The reduced size does not compromise the valve’s functionality, and it can be easily integrated into complex systems.

Improved Flow Control: The wedge gate provides a positive seal, which prevents leakage and enhances flow control. The valve opens and closes quickly and reliably, providing consistent performance even in high-pressure systems.

Versatility: The API 602 valve is versatile and can be used in a wide range of industries, including oil and gas, chemical processing, power plants, and water treatment. It can handle a variety of fluids, including gases, oils, and corrosive chemicals, making it suitable for many different types of applications.

Applications of the API 602 Compact Steel Gate Valve

API 602 compact steel gate valves are used in a variety of applications across different industries, including:

Oil and Gas Industry: These valves are commonly used in upstream and downstream oil and gas operations, including production facilities, refineries, and pipelines. They help control the flow of hydrocarbons and ensure the safety and efficiency of the entire system.

Petrochemical Plants: In petrochemical facilities, where harsh chemicals and high temperatures are common, the API 602 gate valve provides a reliable solution for controlling fluid flow while preventing leaks or contamination.

Power Generation: Power plants use API 602 valves to manage steam, water, and gas flow in high-pressure and high-temperature environments. Their ability to withstand extreme conditions makes them essential components in thermal and nuclear power plants.

Chemical and Pharmaceutical Industries: These valves are used in systems that handle corrosive or hazardous chemicals. Their resistance to corrosion and ability to create a tight seal make them ideal for handling dangerous substances safely.

Water Treatment: In municipal water treatment plants, API 602 valves help regulate the flow of water and wastewater, ensuring that the system remains efficient and leak-free.

Shipbuilding and Marine: The compact size and durability of these valves make them suitable for use in ships and offshore platforms, where space is limited, and reliability is crucial.

Standards and Certifications

The API 602 compact steel gate valve is manufactured according to the API’s rigorous standards, which ensure that the valve performs optimally in demanding applications. The following are some of the key standards and certifications associated with API 602 valves:

API 602: This is the standard for compact steel gate valves, specifying requirements for materials, dimensions, pressure-temperature ratings, and testing.

ASME B16.34: This standard specifies the design, materials, and testing requirements for valves, including pressure and temperature ratings.

ISO 9001: Many manufacturers of API 602 valves adhere to ISO 9001, a quality management standard that ensures consistency in the production of high-quality valves.

API 6D: While this standard applies more generally to valves used in pipeline systems, API 602 valves may also comply with specific portions of this standard, particularly those related to flow and sealing performance.

CE Certification: In certain regions, the valve may require CE marking, indicating compliance with European safety, health, and environmental protection standards.