0102030405

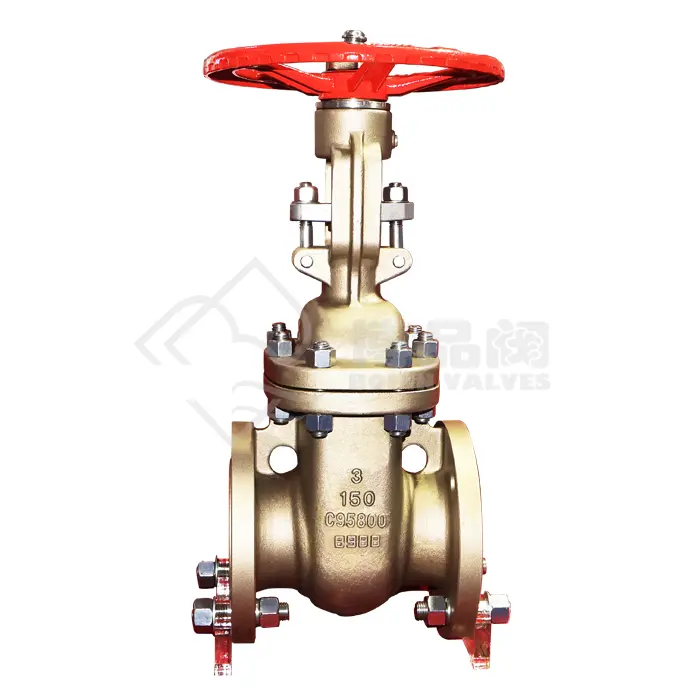

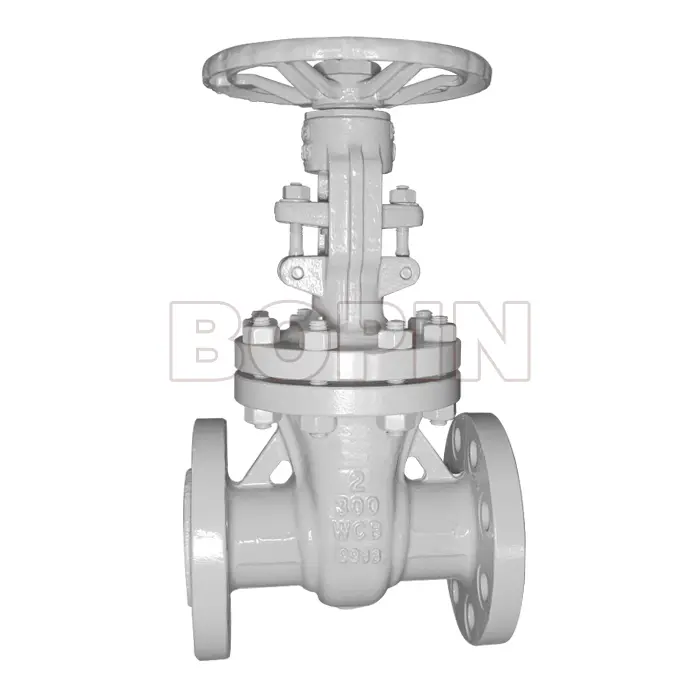

API 600 Cast Steel Manual Wedged Gate Valve

Gate Mechanism: Wedge-Shaped Disc

The defining feature of a wedged gate valve is its gate disc. Unlike parallel gate valves, which have a flat disc, the wedged gate valve has a wedge-shaped disc. This wedge is angled to provide a tight seal against the valve seat when closed. The design of the wedge also helps compensate for thermal expansion and provides better sealing capabilities, especially in high-pressure applications.

The disc typically moves up and down perpendicular to the flow of fluid. When the valve is fully open, the disc is lifted entirely from the flow path, allowing unrestricted flow of the fluid. When the valve is closed, the wedge-shaped disc is forced into a seat, creating a tight seal.

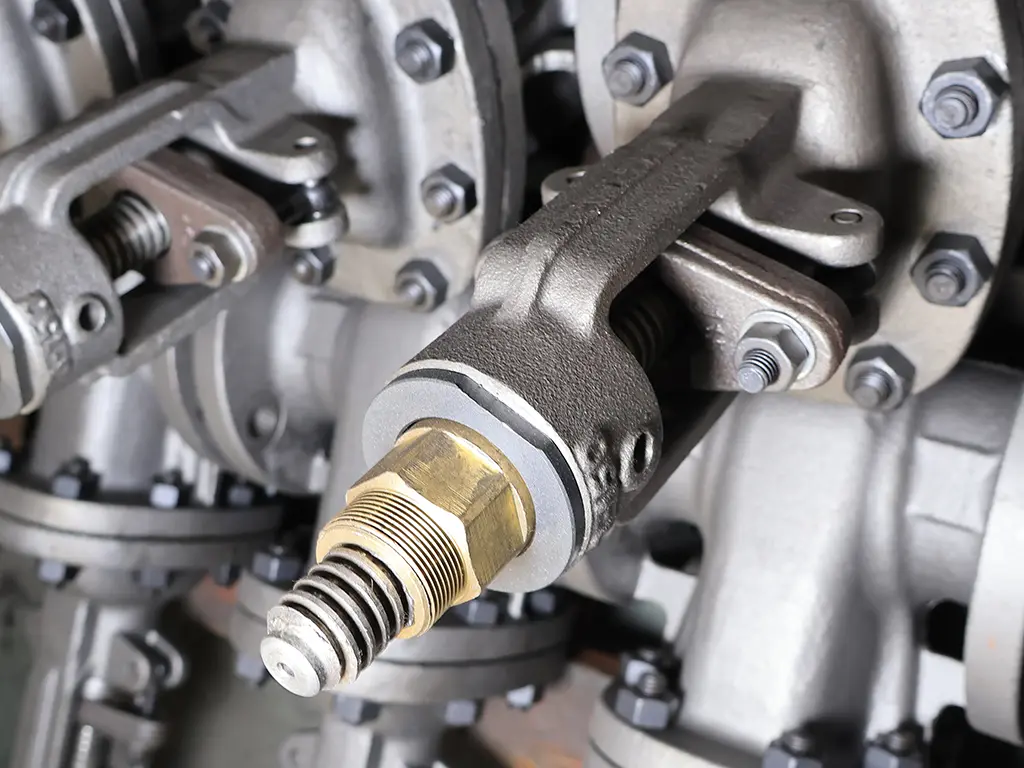

Bonnet and Stem Assembly

The bonnet houses the stem and acts as the cover for the valve body, sealing the valve mechanism inside. The stem connects to the handwheel or actuator outside the valve, allowing the operator to open or close the valve. The manual operation of the valve is achieved through a handwheel or gear mechanism that rotates the stem, which in turn moves the gate.

In the API 600 valve, the stem is typically made from stainless steel or other corrosion-resistant materials to prevent failure due to exposure to harsh fluids or high temperatures.

Seals and Gaskets

Sealing components such as gaskets, packing, and O-rings are essential to preventing leaks and ensuring a tight shutoff when the valve is closed. The packing around the stem prevents leakage of fluids through the stem area. Additionally, metal-to-metal seals are often used in high-pressure applications where elastomeric seals might fail due to extreme conditions.

Working Principle

The API 600 Cast Steel Manual Wedged Gate Valve operates based on a linear motion mechanism. The valve opens and closes by moving a gate (or disc) along a vertical axis. The gate moves in and out of the flow path, either fully obstructing the flow or allowing unrestricted passage, depending on the position of the gate.

Opening: When the operator turns the handwheel in a clockwise direction (or counterclockwise, depending on the design), the valve stem moves, and the wedge gate is pulled up out of the valve body, allowing the fluid to flow freely through the valve.

Closing: When the valve is to be shut, the operator turns the handwheel in the opposite direction. This action forces the gate into a wedged position against the valve seat, creating a seal. The wedge design ensures a tight closure that can withstand the pressure and temperature of the system.

One of the key benefits of the wedged design is that the seal improves as the pressure increases, which helps to minimize the risk of leakage under extreme conditions.

Key Advantages of API 600 Cast Steel Manual Wedged Gate Valve

Durability and Strength

One of the most notable advantages of the API 600 valve is its robust construction. Cast steel provides superior strength and resistance to wear and tear under extreme conditions, making it ideal for demanding industrial environments. The wedge disc design also adds to the strength, ensuring that the valve performs reliably even under high-pressure conditions.

Tight Sealing and Leak Prevention

The wedged gate valve’s sealing capability is enhanced by the wedge-shaped disc, which tightly fits against the valve seat when closed. This prevents leaks and ensures the valve performs efficiently, even in high-pressure or high-temperature systems.

Ease of Maintenance

Manual gate valves are relatively simple to maintain, especially compared to more complex valves like control valves or pressure relief valves. With fewer moving parts and a simple design, maintenance typically involves periodic checks on the gate, stem, and seals. If any components show signs of wear or damage, they can be replaced relatively easily, which helps reduce downtime.

Versatility

API 600 Cast Steel Manual Wedged Gate Valves are highly versatile and can be used in a wide range of applications. Whether in the oil and gas industry, power plants, or chemical processing facilities, these valves can handle a variety of fluids, from water to high-viscosity oils and gases. The valve can be configured for both upstream (flowing into the valve body) and downstream (flowing out of the valve body) applications.

F304/F316 (Stainless Steel): Offers excellent corrosion resistance for aggressive environments.

Applications

Oil and Gas: These valves are used for controlling the flow of crude oil, natural gas, and refined products in pipelines and processing facilities. The wedge design provides excellent sealing, which is crucial in preventing leaks in high-pressure systems.

Power Generation: In power plants, the API 600 valve is used for steam and water flow control in critical systems, including boiler feed water and cooling water systems.

Petrochemical and Chemical: In petrochemical plants, these valves regulate the flow of various chemicals and gases, often under high temperature and pressure conditions.

Water Treatment: These valves are also used in water and wastewater treatment facilities for controlling the flow of water or slurry in pipelines.

Maintenance and Care

Regular Inspection

To ensure the valve operates efficiently, regular inspection is essential. The valve body, gate, stem, and seals should be checked for any signs of wear, corrosion, or damage. Leaks around the stem area or body might indicate a need for seal replacement.

Lubrication

The stem and bonnet assembly should be properly lubricated to minimize friction and wear during valve operation. This helps to extend the life of the valve and ensure smooth operation.

Seal Replacement

Over time, the seals and gaskets can degrade due to exposure to heat, pressure, and aggressive fluids. Regular replacement of these components is necessary to maintain a tight seal and prevent leakage.

Stem Maintenance

The stem should be checked periodically for signs of rust or wear. Any damage to the stem could result in a malfunction of the valve. If the valve becomes difficult to operate, this could be a sign that the stem needs attention, such as cleaning or replacing.