0102030405

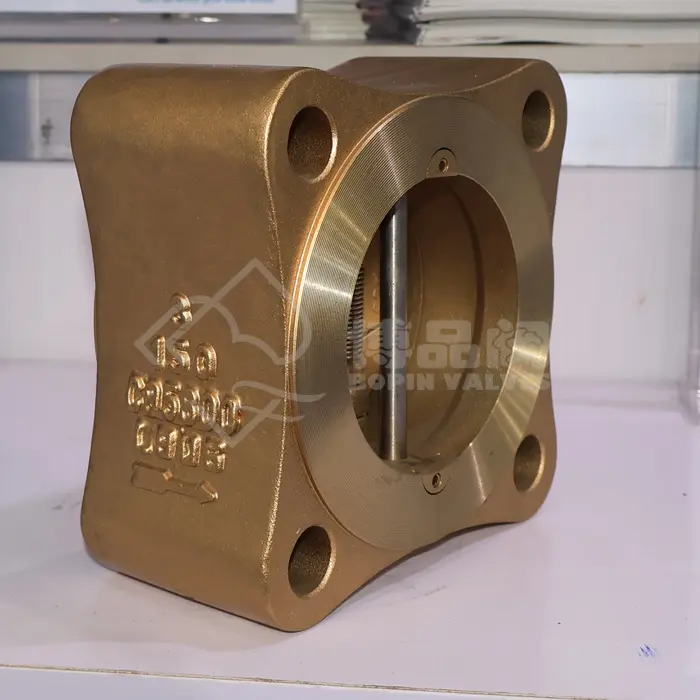

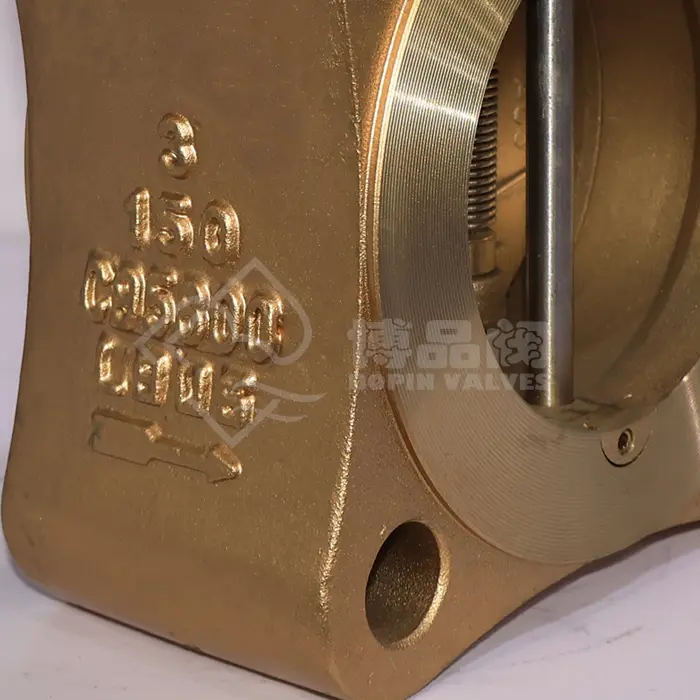

API 594 C95800 LUG TYPE ALUMINUM BRONZE DUAL PLATE CHECK VALVE

Overview of the API 594 Standard

The API 594 standard is a specification set by the American Petroleum Institute (API) that governs the design and manufacturing of check valves for use in petroleum, petrochemical, and natural gas industries. This standard ensures that the check valve operates under specific conditions, including high pressure, temperature fluctuations, and corrosive environments. The API 594 standard applies to dual plate check valves, which are known for their lightweight, compact design and effective performance.

Retainerless Design

The retainerless design of the valve is one of its most important features. In traditional check valves, a retainer or cage holds the internal components (such as the plates or discs) in place. However, this design can increase the complexity, size, and weight of the valve. By eliminating the need for a retainer, the retainerless design improves reliability, reduces potential leakage points, and simplifies manufacturing and maintenance processes.

The C95800 material used in this valve is an aluminum bronze alloy, known for its excellent corrosion resistance, particularly in seawater and aggressive environments. This material is ideal for applications where durability and longevity are essential, and it provides superior mechanical properties compared to standard bronze or brass. The C95800 aluminum bronze allows for the manufacturing of lightweight, high-strength, and highly durable components.

Lug Type Check Valve Design

The lug type configuration of the valve refers to the valve’s mounting method. Unlike flanged valves, which are bolted on both sides, lug type valves are designed to be mounted with bolts only on one side, allowing them to be installed between two flanges. This feature makes lug type valves more versatile in applications where easy maintenance and replacement are essential. The lug type design is particularly useful in systems where space is limited, as it allows for easier disassembly without the need to remove adjacent piping.

This type of check valve is used primarily in systems where the flow direction is critical, as it ensures that fluid or gas only flows in one direction. The dual plate configuration further enhances the valve's performance by using two spring-loaded plates to open and close the valve. These plates automatically adjust to the flow conditions, providing fast and efficient sealing.

Dual Plate Check Valve Functionality

A dual plate check valve works by allowing fluid to flow freely in one direction, while automatically blocking backflow in the opposite direction. This is achieved through the use of two hinged plates, which are spring-loaded and move in response to the flow of the fluid. The design ensures minimal pressure drop, reduced turbulence, and a quick response to changes in flow conditions.

When fluid flows in the intended direction, the plates are pushed open, allowing the fluid to pass. If the flow reverses, the plates swing shut, creating a seal to prevent backflow. This feature is particularly important in systems that require preventing reverse flow, such as in piping systems, pumps, compressors, and heat exchangers.

The dual plate configuration is highly effective in reducing the risk of water hammer (the shock wave that can occur when fluid suddenly changes direction or stops flowing) because the plates close slowly and smoothly, mitigating the potential damage to the system.

Benefits of C95800 Aluminum Bronze Material

The choice of C95800 as the material for this check valve is highly advantageous for a range of applications. C95800 is a copper-based alloy that incorporates both aluminum and iron, giving it superior resistance to corrosion, particularly in seawater and acidic environments. Its exceptional wear resistance and high tensile strength make it a preferred choice for high-pressure applications where valves must withstand repeated cycles of opening and closing.

Corrosion Resistance: The alloy’s natural resistance to corrosion, especially in seawater and saline environments, makes it ideal for offshore and marine applications.

Strength: C95800 provides a high tensile strength, ensuring that the valve can handle higher pressures and temperatures without deforming.

Durability: The material’s wear resistance ensures the valve remains effective over a long lifespan, even in harsh operational conditions.

Low Maintenance: The durability of aluminum bronze reduces the frequency of valve repairs and replacements, thus lowering overall maintenance costs.

High Thermal Conductivity: Aluminum bronze has better thermal conductivity compared to other metals, which allows for more stable operation under varying temperature conditions.

Applications of Aluminum Bronze Dual Plate Check Valve

This valve’s versatility and robust construction make it suitable for a wide variety of applications. Here are some industries and systems where this check valve is commonly used:

1. Oil and Gas Industry

In the oil and gas industry, preventing backflow and ensuring the safety and efficiency of fluid transport systems is crucial. The API 594 retainerless check valve can be found in pipelines, pressure control systems, and separators. The corrosion-resistant properties of the C95800 aluminum bronze make it ideal for offshore drilling rigs, refineries, and petroleum storage systems.

2. Water Treatment Plants

In water treatment and distribution systems, maintaining one-directional flow is vital for preventing contamination and maintaining pressure. The dual plate check valve is used in water treatment plants, pump stations, and distribution networks. The valve’s ability to withstand corrosive substances and high pressures ensures consistent, reliable operation.

3. Chemical Processing

In chemical processing facilities, especially where highly corrosive chemicals are transported, the durability and resistance of the aluminum bronze material are essential. This check valve is often used in pipelines carrying chemicals, acids, or other aggressive fluids, as it prevents backflow and ensures the integrity of the system.

4. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, check valves prevent the backflow of refrigerants and other fluids. The valve’s dual plate design minimizes pressure loss while effectively controlling fluid flow, making it a great choice for energy-efficient HVAC systems.

5. Marine and Offshore Applications

For marine vessels and offshore platforms, which are subjected to harsh environmental conditions, the C95800 aluminum bronze check valve is a preferred option. Its corrosion resistance and robust construction provide long-lasting performance in seawater and other marine environments.

Advantages of the Dual Plate Check Valve Design

The dual plate check valve offers several advantages over other types of check valves, such as swing check valves and ball check valves:

Lower Pressure Drop: Due to the streamlined design and lightweight plates, the dual plate check valve minimizes pressure drop across the valve, which improves the efficiency of the entire system.

Compact Design: The compactness of the dual plate check valve allows for easier installation in confined spaces, which is beneficial in areas with limited space.

Reduced Weight: The dual plate design is lighter than other types of check valves, making installation and maintenance easier.

Quick Response Time: The dual plates react faster to flow changes, providing faster closure and minimizing the risk of backflow.

Cost-Effectiveness: Due to its efficient design and material properties, the dual plate check valve offers a cost-effective solution for high-performance fluid control.