0102030405

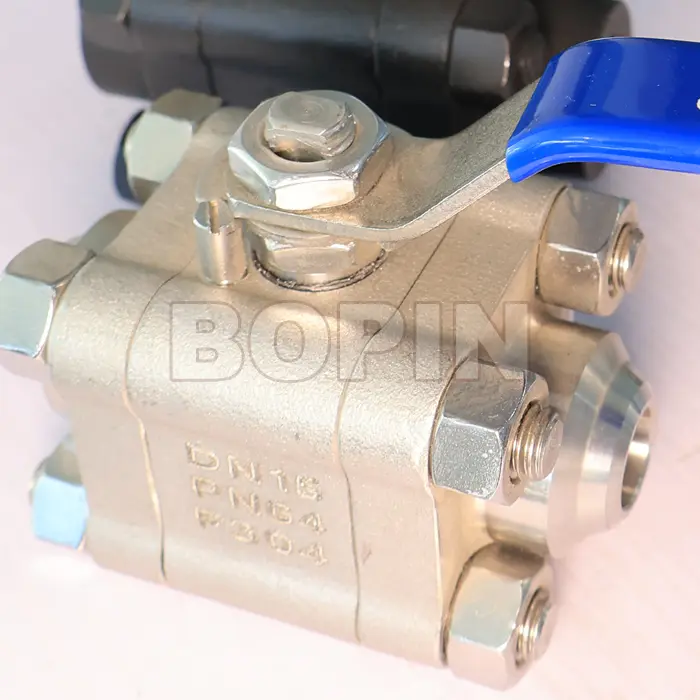

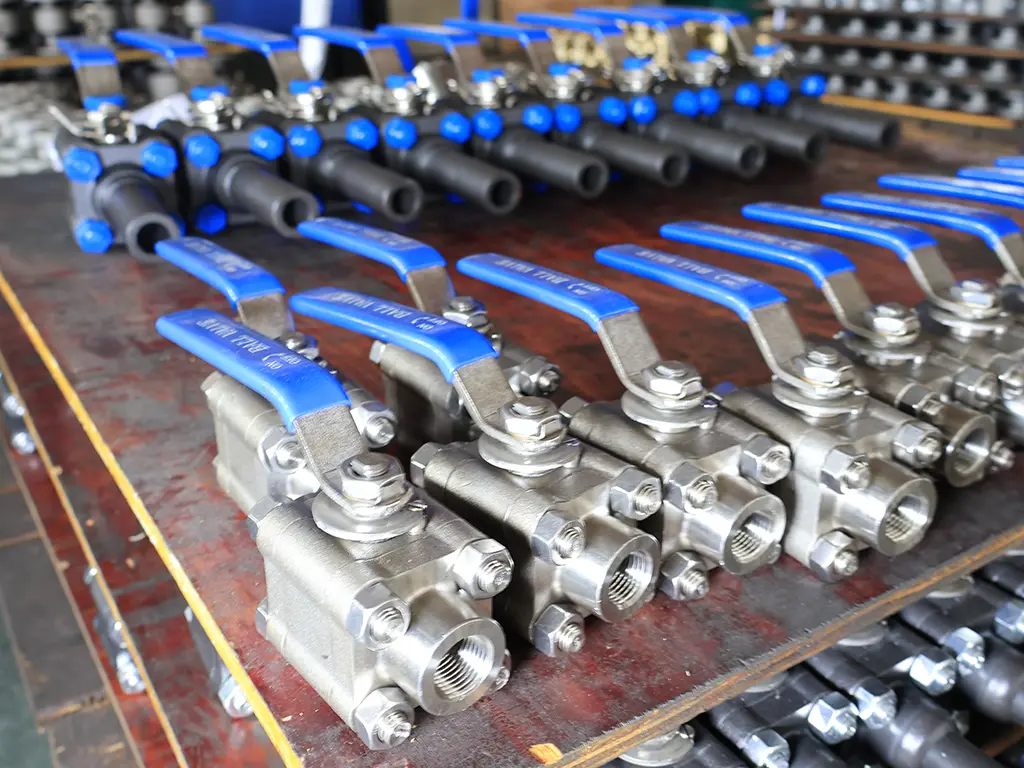

182 F304 HANDLE TYPE 3-PC BODY BUTT-WELDED END FLOATING TYPE FORGED STEEL BALL VALVE

Material Specification: A182 F304 Forged Steel

ASTM A182 F304 refers to a forged austenitic stainless steel, which is known for its excellent corrosion resistance, mechanical strength, and weldability.

304 stainless steel is composed primarily of iron, with 18-20% chromium and 8-10.5% nickel. This combination provides high resistance to oxidation and corrosion, especially in mildly corrosive environments.

The forging process enhances the material’s grain structure, increasing its tensile strength and toughness, making it ideal for high-pressure service.

It also offers good machinability and excellent surface finish after fabrication.

304 stainless steel is composed primarily of iron, with 18-20% chromium and 8-10.5% nickel. This combination provides high resistance to oxidation and corrosion, especially in mildly corrosive environments.

The forging process enhances the material’s grain structure, increasing its tensile strength and toughness, making it ideal for high-pressure service.

It also offers good machinability and excellent surface finish after fabrication.

Valve Design of 3-PC Split Body

The 3-piece body design consists of two end caps and a central body. This construction offers ease of maintenance, allowing operators to remove the center section for cleaning, inspection, or repair without removing the valve from the pipeline.

A split body allows for better alignment of internal components and is especially useful in high-pressure applications as it minimizes leakage potential.

Body joints are sealed with high-integrity gaskets (typically PTFE, graphite, or metal), ensuring leak-proof performance.

A split body allows for better alignment of internal components and is especially useful in high-pressure applications as it minimizes leakage potential.

Body joints are sealed with high-integrity gaskets (typically PTFE, graphite, or metal), ensuring leak-proof performance.

Ball Design of Floating Type

In a floating ball valve, the ball is not fixed but held in place by two elastomeric or metal seats. Under pressure, the ball moves slightly downstream, pressing tightly against the seat to ensure a positive seal.

This design is ideal for low to medium pressure systems, providing bubble-tight shutoff and requiring low operating torque.

Typically, anti-blowout stems and anti-static devices are incorporated to enhance safety and prevent build-up of static electricity during flow of flammable fluids.

This design is ideal for low to medium pressure systems, providing bubble-tight shutoff and requiring low operating torque.

Typically, anti-blowout stems and anti-static devices are incorporated to enhance safety and prevent build-up of static electricity during flow of flammable fluids.

Connection Type of Butt-Welded End

The butt-welded ends are designed to be welded directly to the piping system, forming a permanent, robust, and leak-proof connection.

This type of end connection is favored in high-pressure, high-temperature, or hazardous service environments where mechanical joints are less reliable.

Butt-welding allows for smooth internal bore alignment, reducing pressure drop and turbulence across the valve, which is critical in systems handling viscous or sensitive fluids.

Operation of Manual Handle Type:

The manual lever handle provides a simple and reliable method of valve operation. By turning the handle 90 degrees, the valve opens or closes fully, allowing for quick shutoff or flow control.

The position of the handle offers visual indication of the valve status (open or closed), which is crucial for manual operation.

Handles are typically equipped with a locking mechanism for added safety, preventing accidental operation in critical applications.

This type of end connection is favored in high-pressure, high-temperature, or hazardous service environments where mechanical joints are less reliable.

Butt-welding allows for smooth internal bore alignment, reducing pressure drop and turbulence across the valve, which is critical in systems handling viscous or sensitive fluids.

Operation of Manual Handle Type:

The manual lever handle provides a simple and reliable method of valve operation. By turning the handle 90 degrees, the valve opens or closes fully, allowing for quick shutoff or flow control.

The position of the handle offers visual indication of the valve status (open or closed), which is crucial for manual operation.

Handles are typically equipped with a locking mechanism for added safety, preventing accidental operation in critical applications.

Key Features and Benefits

Corrosion Resistance: A182 F304 stainless steel offers superior corrosion resistance in water, air, chemical, and low-temperature environments.

Ease of Maintenance: The 3-PC design allows for easy in-line service without removing the valve from the pipeline.

Leak-Proof Performance: Floating ball design ensures tight sealing under varying pressure conditions.

Durability: Forged construction increases strength and extends service life in demanding conditions.

Welded Ends: Ideal for permanent installations with minimized risk of leakage over time.

Fire-Safe Design: Many 3-PC floating ball valves are compliant with API 607 or ISO 10497, ensuring performance in fire-exposed conditions.

Blowout-Proof Stem: Prevents the stem from being ejected during high-pressure service, improving safety.

Applications

This valve type is extensively used in:

Oil & Gas: Used in upstream, midstream, and downstream applications for isolation of hydrocarbons, gas flow control, and pipeline systems.

Chemical Processing: Handles aggressive fluids, acids, and solvents without corroding.

Power Generation: Suitable for high-pressure steam, condensate, and cooling systems.

Petrochemicals: Used in refining processes requiring precise flow control.

Pharmaceuticals and Food Industry: When made with hygienic standards, it's suitable for sterile and clean environments.

Cryogenic Applications: With special trim, suitable for low-temperature service.

Standards and Certifications

A182 F304 floating ball valves comply with various international standards to ensure safety, performance, and quality:

ASME B16.34: For pressure-temperature ratings and general valve construction.

API 6D / API 608: For design and performance of ball valves in pipeline service.

ANSI B16.25: For butt-welding ends.

API 607 / ISO 10497: Fire-safe performance testing.

NACE MR0175 / ISO 15156: For resistance to sulfide stress cracking in sour service.

Maintenance & Installation

Installation: Proper alignment is crucial; ensure clean welding to prevent seat damage. Post-weld heat treatment may be required based on service.

Maintenance: Periodic inspection of seals and seats is recommended. The 3-PC body allows quick disassembly for internal inspection without line removal.

Spare Parts: Available from manufacturers for seats, gaskets, stem packing, and handles, allowing for long service life.